ISO Qaulity Hammer Crusher Granite Limestone Coal Hammer Crusher

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Type:Hammer Crusher

- Application:Construction, Mineral Industry, Stone Industry

- Drive:Electric

- Crushing Style:Impact

- Compressive Strength (For Crushing):250-300MPA

- Crushing Degree:Fine Grinding Machine

Base Info

- Model NO.:PC series

- Certification:CE, ISO

- Condition:New

- Color:Yellow

- Roror Speed(R/Min):750-1440

- Feeding Size(Mm):Not Bigger Than 250

- Output Size(Mm):Not Bigger Than 20

- Weight(Kg):900-19000

- Installation:Engineers Guided

- After-Sale Service:We Offer

- Transport Package:Standard Container

- Specification:CE, SGS

- Trademark:Hengchang

- Origin:Gongyi City Guangling Road No. 6, Henan, China

- HS Code:847410000

- Production Capacity:100 Sets,Month

Description

Basic Info.

Model NO. PC series Certification CE, ISO Condition New Color Yellow Roror Speed(R/Min) 750-1440 Feeding Size(Mm) Not Bigger Than 250 Output Size(Mm) Not Bigger Than 20 Weight(Kg) 900-19000 Installation Engineers Guided After-Sale Service We Offer Transport Package Standard Container Specification CE, SGS Trademark Hengchang Origin Gongyi City Guangling Road No. 6, Henan, China HS Code 847410000 Production Capacity 100 Sets/MonthProduct Description

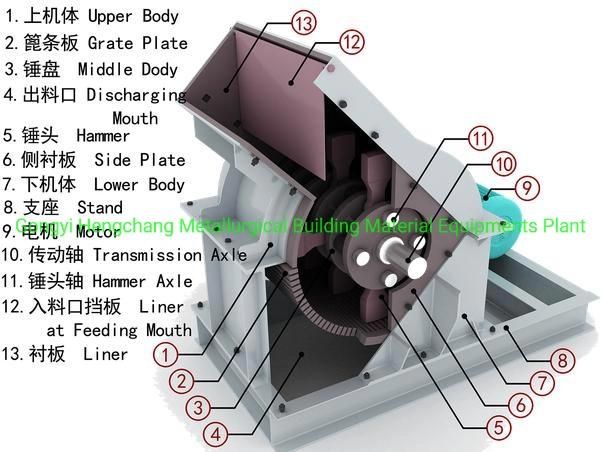

Hammer Crusher introduction

Hammer crusher use the impact force between high-speed rotating hammers and materials to do the break work.

Hammer crusher has the advantages of simple structure, large crushing ratio and high production efficiency etc.

And can crush in dry & wet way. It is widely used in to crush the medium hardness and brittleness materials in mining, cement, coal, metallurgy, building materials, roads, fuel and other departments. The grate gap of hammer crusher can be adjusted to meet different particle size as requirements.

Features of hammer crusher

1. High quality chrome hammer, abrasion resistance achieving the advanced level in country;

2. Specially designing tooth impact plate;

3. Adjustable discharge open;

4. Low power consumption unit;

5. Big crushing ratio

6. Very long operation life

7 Simple structure, reliable operation

8. Easy maintenance, low operation cost

9. Good operating safety, lower energy cost

10. High economic efficiency, low cost, fast recovery

Working principle of hammer crusher

When the materials get into the working area of hammers, the rotating hammers with high rotation speed are crushing them, the crushed products meeting the required size can be discharged by the outlet and become the final products, the large size products are brought back to the crushing area by the hammers for being re-crushed until they reached the required size. When the bulk material into the machine, hit by the hammerhead and stopped by material bracket. That's not only increase the contact area between material and hammerhead but also avoid sudden infarction of the rotor. After the impact, bulk materials hit themselves on the crushing cavity. Then the stones overflow from the straight screen or falling and been hammered again forming the stones. At last discharged from outlet of the hammer crusher

Technical data

| Model | Rotor Size (Diameter×length ) (mm) | Rotor Speed (r/min) | Feeding Size (mm) | Output Size(mm) | Motor power (KW) | Capacity(t/h) | Weight (kg) |

| PC400×300 | Φ400×300 | 1440 | ≤100 | ≤10 | 7.5 | 5-10 | 900 |

| PC600×400 | Φ600×400 | 960 | ≤100 | ≤15 | 18.5 | 10-20 | 1500 |

| PC800×600 | Φ800×600 | 970 | ≤120 | ≤15 | 45 | 18-24 | 2680 |

| PC1000×800 | Φ1000×800 | 990 | ≤200 | ≤15 | 110 | 30-50 | 5600 |

| PC1000×1000 | Φ1000×1000 | 990 | ≤200 | ≤15 | 132 | 30-60 | 8000 |

| PC1200×1200 | Φ1200×1200 | 750 | ≤250 | ≤20 | 180 | 90-110 | 19000 |