Large Crushing Ratio Rock Gravel Making Machine

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Type:Impact Crusher

- Application:Machinery & Hardware, Art & Craft, Chemical, Construction, Mineral Industry, Stone Industry

- Drive:Electric

- Crushing Style:Grinding & Impact

- Compressive Strength (For Crushing):>300MPA

- Crushing Degree:Coarse Crusher

Base Info

- Model NO.:PF-1007

- Finished Surface:Cut Off Tool

- Certification:CE, ISO

- Condition:New

- Color:at The Different Design

- Name:Large Crushing Ratio Rock Gravel Making Machine

- Keyword:Rock Gravel Making Machine

- Weight:6.5t

- Working Condition:Durable

- Power:30-350kw

- Delivery Time:15 Days

- Guarantee:12month

- After Sale Service:Long Term, Good Price

- Installation:Under Our Guide

- Spare Parts Supply:Long Term, Good Price

- Crusher Material:Carbon Steel

- Crusher Color:Customized

- Hammer Material:High Manganese Material

- Crusher Feature:High Efficience

- Payments:T,T

- Transport Package:Standard Packing

- Specification:CE

- Trademark:HC

- Origin:Gongyi City, Henan Province, China

- HS Code:8474201000

- Production Capacity:300 Set,Sets Per Month

Description

Basic Info.

Model NO. PF-1007 Finished Surface Cut Off Tool Certification CE, ISO Condition New Color at The Different Design Name Large Crushing Ratio Rock Gravel Making Machine Keyword Rock Gravel Making Machine Weight 6.5t Working Condition Durable Power 30-350kw Delivery Time 15 Days Guarantee 12month After Sale Service Long Term, Good Price Installation Under Our Guide Spare Parts Supply Long Term, Good Price Crusher Material Carbon Steel Crusher Color Customized Hammer Material High Manganese Material Crusher Feature High Efficience Payments T/T Transport Package Standard Packing Specification CE Trademark HC Origin Gongyi City, Henan Province, China HS Code 8474201000 Production Capacity 300 Set/Sets Per MonthProduct Description

1. Introduction of Large crushing ratio rock gravel making machineStone Impact Crusher is widely used to crush the medium hardness brittle materials such as limestone, dolomite, shale, sandstone, coal, asbestos, graphite, and rock salt etc. In building materials, chemicals, coal and other industries. It has the advantages of large crushing ratio, usually 10-20, and maximum 50-60; Simplified crushing process, unique structure, easy manufacture, and convenient operating and maintenance.

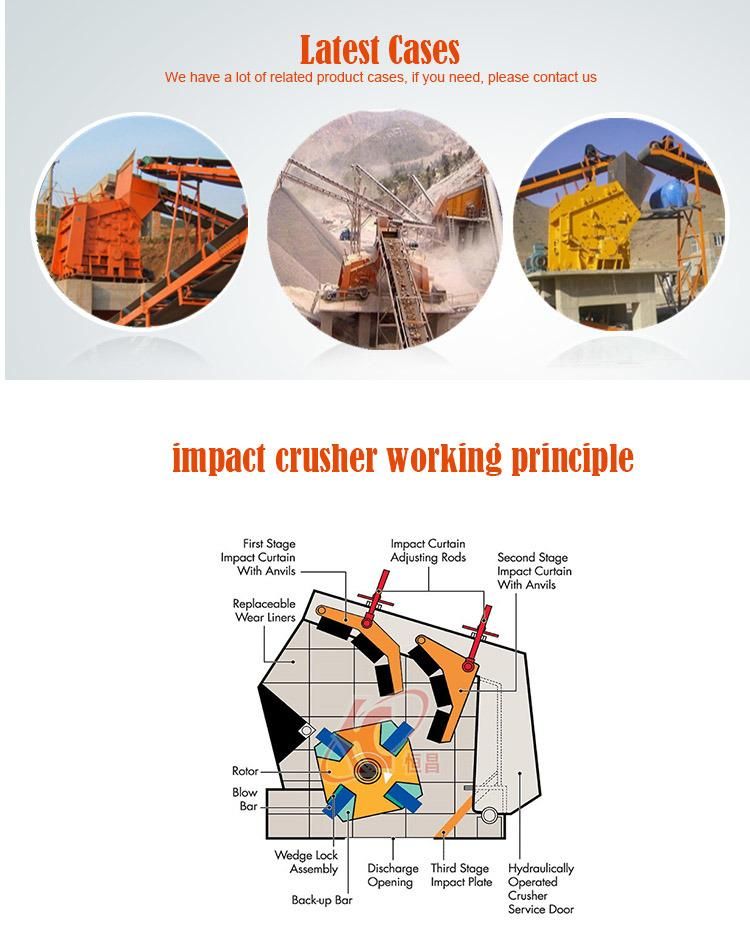

2. Work principle of Large crushing ratio rock gravel making machine

Compare to other crushers, our impact crusher has bigger reduction ratio and can fully use the high speed impactenergy of entire rotor. But because the impact crusher board hammer isextremely easy to wear, it also is restricted in the hard material staveapplication. Impact crusher is usually used to break thick garrulous, garrulousor the limestone, the coal, the calcium carbide, the quartz, the dolomite, thecuring iron ore, the gypsum and the industrial chemicals which are hardfollowing brittle material.

The ideal entering material granularity of our PF type impact crusher is 100-500mm, themost greatly is not surpass the rating. The materail granularity user canajusts the hammer head and the impact board and th gap between component, according to theirs demands.

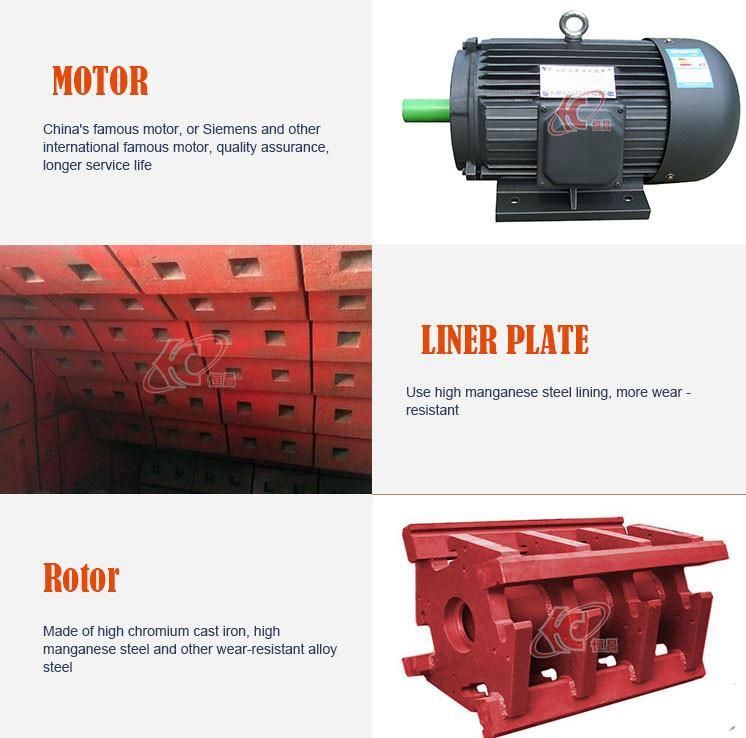

3. Main Features of Large crushing ratio rock gravel making machine

1) Optimized design to low-speed, multi-impact crusher crushing chamber, the back-breaking than the average line speed reduced by 20% -25%, with low power consumption for high production capacity

2)A new manufacturing technology, the successful development of a high wear resistance, high toughness of chromium, molybdenum, vanadium alloy, to solve the problem of fragmentation of hard materials. Greatly improving the life of the board hammer

3)Simplified crushing process

4) Feed opening, high crushing chamber to meet the high material hardness, block degree, the product powder less

4.Technical Data of Large crushing ratio rock gravel making machine

Model | Rotor Size (mm) | Max.Input Size (mm) | Output size (mm) | Motor power (kw) | Capacity (t/h) | Weight (kg) |

PF_0807 | 850 × 700 | 300 | ≤ 25=85% | 30 | 10-25 | 3500 |

PF_1007 | 1000 × 700 | 300 | ≤ 25=85% | 37 | 15-30 | 6500 |

PF_1010 | 1000 × 1050 | 350 | ≤ 25=85% | 55-75 | 50-80 | 12100 |

PF_1210 | 1250 × 1050 | 350 | ≤ 25=85% | 110-132 | 70-120 | 14000 |

PF_1214 | 1250 × 1400 | 400 | ≤ 25=85% | 132-160 | 130-180 | 18500 |

PF_1315 | 1300 × 1500 | 500 | ≤ 25=85% | 160-200 | 180-260 | 23500 |

PF _ 1320 | 1320× 2000 | 500 | ≤ 25=85% | 300-350 | 300-350 | 26500 |

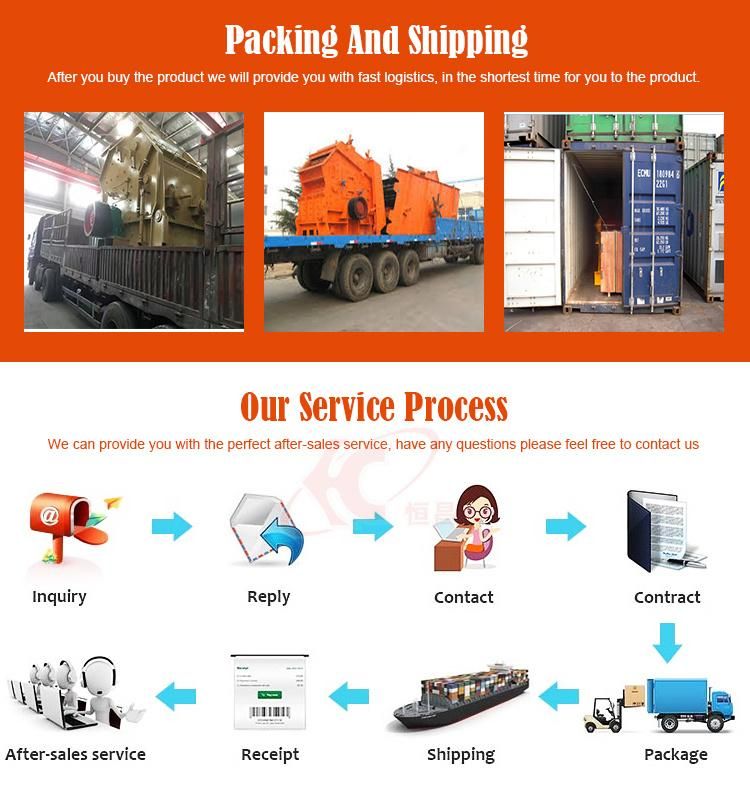

5. Our service

(1)Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

(2)After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

6. Our copmany

7. Buying Guides

To choose the appropriate model for you ,can you tell me:

(1) What's the raw materials(such as limestone) and its size(mm/inch)?

(2). What do you neeed ?a machine or a stone production line ?

(3). What's the required capacity(tons per hour or t/h)?

FAQ:

1 Are you a trading company or manufacturer? What is your main products?

We are a manufacturer, Our factory name is Gongyi Hengchang metallurgical building materials equipments plant. which has over 25 years of experience in this industry. Our Main products are Jaw crusher,Impact crusher,Cone crusher,Hammer crusher,Vibration feeder,Vibration screen,sand/stone washing machine,ball mill,flotation machine,Disc pelletizer, concentrator,Rotary dryer,Conveyor machine ,Briquette machine , Mixer ,Roller grinder and so on,We produce products divided into Stone prodution line and Sand-making productiong line,

Magnetic separating process ,Flotation separating process ,Gravity separating process ,Coal and mineral powder briguetting .

2 Can I visit your factory and clients' workshop? How to get to your factory?

Yes, welcome to visit our factory anytime, we can also arrange your visit in our China clients' workshop.

For getting to our factory, you can get a flight to Zhengzhou Airport. It just takes about 2 hour from Zhengzhou Airport to our factory by car.

3 What is your guarantee time and aftersale service?

--Our guarantee time is 1 years.

--EEach order machine we provide installation drawing and operation manual. If needed, engineers can be sent to your factory for installation and commissioning, training.

--Any problem in operation or others about machines, we will give solution in 12-24hours.

4 What is your payment term?

We can accept various payment terms if it is convenient for you.

5 What is your delivery time?

Machine leadtime is 7 working days in standard specification, 15~20 working days if customized.

Pls tell your questions,Hengchang factory team are happy to serve&ready to be your business partner! If you want to know more details, please contact Winni ! Your satisfaction is our greatest pursuit.