Waste Brick, Construction Waste Screening Plant for Fuel (PFS1313)

ATAIRAC ENGINEERED PRODUCTS INC(CHINA)- Type:Impact Crusher

- Application:Machinery & Hardware, Chemical, Construction, Mineral Industry, Stone Industry

- Drive:Electric

- Crushing Style:Impact

- Compressive Strength (For Crushing):100-250MPA

- Crushing Degree:Intermediate Crusher

Base Info

- Model NO.:PFS1313

- Certification:CE, ISO

- Condition:New

- Color:Yellow

- Max Feed Size:0-500mm

- Output Size (mm):40

- Capacity (Tph):180-260

- Power (Kw):200

- Origin:China

Description

Weight (t)Thickness*width*length (mm) 2PGC90120 200*500*800 50-150 60-150 37-59 18 2PGC90160 300*700*1000 50-150 80-200 75-92 23 2PGC90200 400*1200*1500 50-150 100-250 92-120 30

Brief introduction of us

Atairac is a high-tech enterprise specializing in R&D, manufacturing, project planning, construction design, process flow design, intelligent automation control of the system, and overall operation and delivery of equipment in the field of crushing, grinding, screening, feeding, conveying, environmental protection and dust removal of all kinds of minerals, rocks and construction waste treatment and utilization.

At present, the rapid development and large-scale construction in all parts of the country have brought about a large amount of construction waste, which has become a new obstacle affecting urban development and environmental and ecological deterioration.

Based on the principle of recycling and utilization, relying on years of experience in comprehensive treatment of construction waste and other solid wastes, as well as the company's strong technical strength, reliable production and processing equipment, our company devotes itself to perfecting advanced, practical, efficient design concept and reliable equipment from understanding customer's needs to solving customer's needs. Besides,we can provide complete set of system solutions for customers, which can effectively solve the current problems of transportation, stacking and disposal of urban construction waste, save land resources, eliminate environmental pollution, and realize the orderly development of urban ecological environment protection and circulation.

Classification of Construction Waste

According to the source, construction waste can be divided into five categories: land excavation,road excavation, demolition of old buildings and construction materials production waste, and they are mainly composed of concrete blocks, brick and tile fragments, slag, gravel, waste mortar, asphalt blocks, waste plastics, waste metal materials, waste packaging materials, waste bamboo and wood, etc.

Harm of Construction Waste

1. Occupying land, wasting land resources and reducing soil quality

2. Destroying and deteriorating the surrounding environment and affecting air quality

3. Pollution and destruction of waters

4. Waste of resources, increase the cost of clearance

Treatment and Utilization of Construction Waste

At present, urban construction waste can be broken, sorted, screened, cleaned, and separated from metal, light wood and materials, and then the remaining concrete blocks, gravel, brick will be processed into a certain size of recycled aggregate, which can be used in roadbed stone, unburned brick, cement admixture and many other aspects.

Waste bricks, tiles, concrete blocks, wood and other light substances, metal scraps, etc.

1. Building Foundation Reinforcement Materials

2. Road Construction Base Material

3. Paving Bricks for Municipal Construction

4. Non-load-bearing hollow blocks

5. Recycled aggregate for concrete

6. fuel

7. Scrap recovery

We are in action......

As for the coarse, and medium crushing processing of coagulator, concrete secondary product waste and brick-concrete structure of , construction waste crusher has division and crushing dual functions,as well as larger production capacity, lower operating costs, higher treatment of water integration , smooth material bonding , uniformed product size, less over-crushing.

After sorting, removing or crushing, most of the waste can be reused as renewable resources, such as scrap steel prevention, scrap iron wire, scrap wire and various scrap steel fittings. After sorting, centralizing and reboiling, the waste can be reprocessed and manufactured into ready-made steel products: brick, stone, concrete and other waste that can be crushed and used as substitute for sands for mortar, plastering mortar, concrete dyeing layer, etc.They can also be used to make building materials such as blocks, paving bricks and plaid bricks.

At present, the utilization of construction waste resources has been vigorously supported by the state, and many policies have been issued to promote the industrialization of construction waste treatment. For example, the recycling and disposal of construction waste has been included in the model country of municipal public utilities, the government allocates construction land, preferential fiscal and taxation policies, the recycled products of construction waste should be included in the green building materials catalogue, government procurement catalogue, etc.

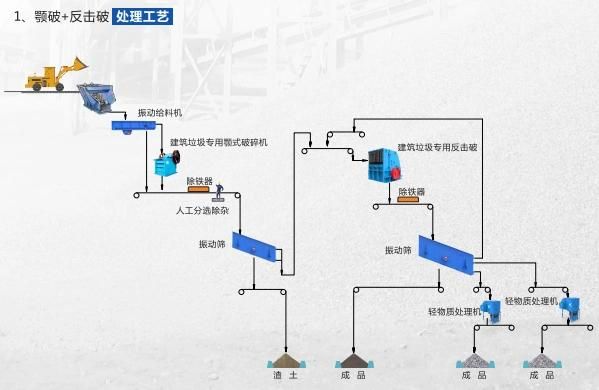

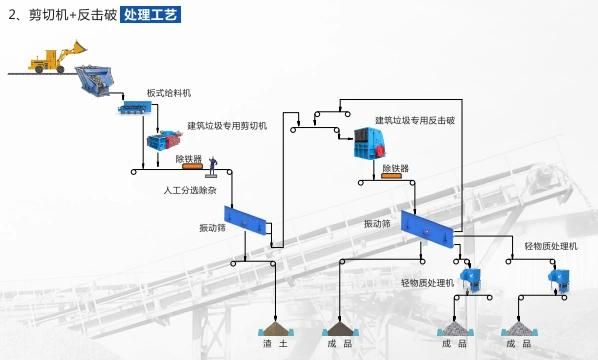

Technological process

With the concept of low-carbon, environmental protection and recycling, our company adopts advanced, reliable and applicable technology and process to recycle construction waste, which effectively solves the problems of transportation, stacking and disposal of construction waste, and can turn construction waste into treasure.

According to the different sources and types of construction waste, different process and equipment configuration can be adopted.

Brief introduction of us

Atairac is a high-tech enterprise specializing in R&D, manufacturing, project planning, construction design, process flow design, intelligent automation control of the system, and overall operation and delivery of equipment in the field of crushing, grinding, screening, feeding, conveying, environmental protection and dust removal of all kinds of minerals, rocks and construction waste treatment and utilization.

At present, the rapid development and large-scale construction in all parts of the country have brought about a large amount of construction waste, which has become a new obstacle affecting urban development and environmental and ecological deterioration.

Based on the principle of recycling and utilization, relying on years of experience in comprehensive treatment of construction waste and other solid wastes, as well as the company's strong technical strength, reliable production and processing equipment, our company devotes itself to perfecting advanced, practical, efficient design concept and reliable equipment from understanding customer's needs to solving customer's needs. Besides,we can provide complete set of system solutions for customers, which can effectively solve the current problems of transportation, stacking and disposal of urban construction waste, save land resources, eliminate environmental pollution, and realize the orderly development of urban ecological environment protection and circulation.

Classification of Construction Waste

According to the source, construction waste can be divided into five categories: land excavation,road excavation, demolition of old buildings and construction materials production waste, and they are mainly composed of concrete blocks, brick and tile fragments, slag, gravel, waste mortar, asphalt blocks, waste plastics, waste metal materials, waste packaging materials, waste bamboo and wood, etc.

Harm of Construction Waste

1. Occupying land, wasting land resources and reducing soil quality

2. Destroying and deteriorating the surrounding environment and affecting air quality

3. Pollution and destruction of waters

4. Waste of resources, increase the cost of clearance

Treatment and Utilization of Construction Waste

At present, urban construction waste can be broken, sorted, screened, cleaned, and separated from metal, light wood and materials, and then the remaining concrete blocks, gravel, brick will be processed into a certain size of recycled aggregate, which can be used in roadbed stone, unburned brick, cement admixture and many other aspects.

Waste bricks, tiles, concrete blocks, wood and other light substances, metal scraps, etc.

1. Building Foundation Reinforcement Materials

2. Road Construction Base Material

3. Paving Bricks for Municipal Construction

4. Non-load-bearing hollow blocks

5. Recycled aggregate for concrete

6. fuel

7. Scrap recovery

We are in action......

As for the coarse, and medium crushing processing of coagulator, concrete secondary product waste and brick-concrete structure of , construction waste crusher has division and crushing dual functions,as well as larger production capacity, lower operating costs, higher treatment of water integration , smooth material bonding , uniformed product size, less over-crushing.

After sorting, removing or crushing, most of the waste can be reused as renewable resources, such as scrap steel prevention, scrap iron wire, scrap wire and various scrap steel fittings. After sorting, centralizing and reboiling, the waste can be reprocessed and manufactured into ready-made steel products: brick, stone, concrete and other waste that can be crushed and used as substitute for sands for mortar, plastering mortar, concrete dyeing layer, etc.They can also be used to make building materials such as blocks, paving bricks and plaid bricks.

At present, the utilization of construction waste resources has been vigorously supported by the state, and many policies have been issued to promote the industrialization of construction waste treatment. For example, the recycling and disposal of construction waste has been included in the model country of municipal public utilities, the government allocates construction land, preferential fiscal and taxation policies, the recycled products of construction waste should be included in the green building materials catalogue, government procurement catalogue, etc.

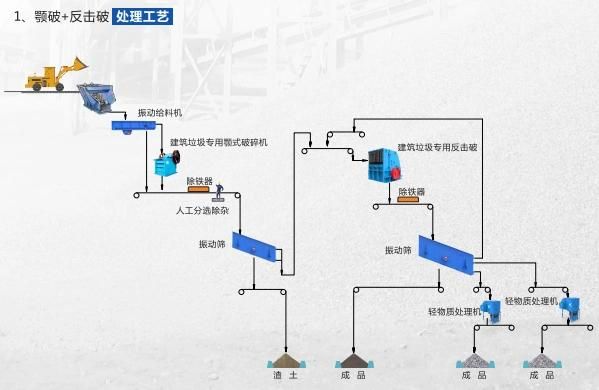

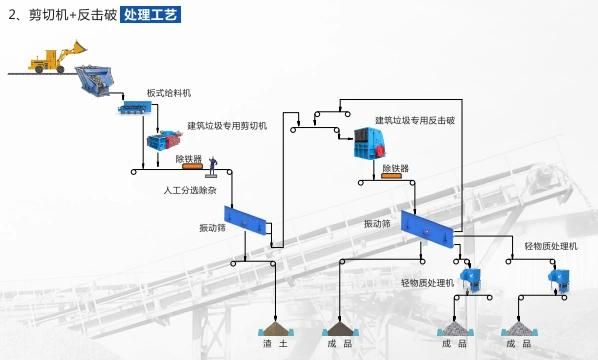

Technological process

With the concept of low-carbon, environmental protection and recycling, our company adopts advanced, reliable and applicable technology and process to recycle construction waste, which effectively solves the problems of transportation, stacking and disposal of construction waste, and can turn construction waste into treasure.

According to the different sources and types of construction waste, different process and equipment configuration can be adopted.