Hummer Scrap Metal Hammer Mill Suppliers Hammer Crusher Machine with Easy Operation

Jiangxi Victor International Mining Equipment Co., Ltd.- Warranty:1 Year

- Type:Hammer Crusher

Base Info

- Model NO.:PC400*300

- Application:Construction, Mineral Industry, Stone Industry

- Drive:Electric

- Crushing Style:Extruding & Milling

- Compressive Strength (For Crushing):<100MPA

- Crushing Degree:Coarse Crusher

- Finished Surface:Thread Process

- Certification:CE, ISO

- Condition:New

- Color:Customer Request

- OEM:Yes

- Shipping Way:by Sea, DHL, FedEx, UPS, TNT, EMS

- Pay Terms:Tt, Paypal, Credit Card, Western Union

- Product Name:Hammer Crusher

- Usage:Dry and Wet Crushing of Brittle, Medium Hard

- Feed Opening Size:400*300mm

- Max Feeding Size:100mm

- Discharge Size:0-30mm

- Capacity:5-8t,H

- Weight:900kg

- Dimension:844*942*878mm

- Transport Package:No Package

- Specification:3206*2210*1515mm

- Trademark:WKD

- Origin:China

- HS Code:8474100000

- Production Capacity:500sets,Month

- Package size per unit product:864.00cm * 962.00cm * 898.00cm

- Gross weight per unit product:920.000kg

Description

Basic Info.

Model NO. PC400*300 Application Construction, Mineral Industry, Stone Industry Drive Electric Crushing Style Extruding & Milling Compressive Strength (For Crushing) <100MPA Crushing Degree Coarse Crusher Finished Surface Thread Process Certification CE, ISO Condition New Color Customer Request OEM Yes Shipping Way by Sea, DHL, FedEx, UPS, TNT, EMS Pay Terms Tt, Paypal, Credit Card, Western Union Product Name Hammer Crusher Usage Dry and Wet Crushing of Brittle, Medium Hard Feed Opening Size 400*300mm Max Feeding Size 100mm Discharge Size 0-30mm Capacity 5-8t/H Weight 900kg Dimension 844*942*878mm Transport Package No Package Specification 3206*2210*1515mm Trademark WKD Origin China HS Code 8474100000 Production Capacity 500sets/MonthPackaging & Delivery

Package size per unit product 864.00cm * 962.00cm * 898.00cm Gross weight per unit product 920.000kgProduct Description

Introduction

Hammer crusher for crushing all kinds of hard and abrasive weak materials. The compressive strength of the material does not exceed 100MPa, moisture content less than 15%. Material to be broken coal, salt, chalk, gypsum, brick, limestone and so on. Also used for crushing fiber structure, strong flexibility and toughness of broken wood, paper or broken asbestos cement waste to recover asbestos fibers and so on. In addition, hammer crusher not only used for crushing production line, sand production line, but also in mineral processing production line replacement cone crusher.

Main Features

1.Inlet large, high crushing chamber adapted material hardness, block degree, the product powder less

2.Materials vacant, broken power consumption

3.New hammer, impact force

4.Hammer shaft mounted adjustable, hammer, long life

5.Grid size is adjustable, controllable particle size, particle shape is good

6.Chassis can be flipped, maintenance more convenient

7.Square shank bolts, impact resistance, wear and tear

8.Compact, machine rigidity

9.Fight structure, handling, easy to install

10.The machine shocks, counter, strike (rock stone) fragmentation functions in a high production efficiency, mechanical abrasion

is small, the overall efficiency significantly, widely used in artificial sand Chinese Small Used Industrial Stone Aggregate Clay Glass Bottle Breaking Hammer Crush Crusher

Working Principle

Big size material feed into the crushing cavity,then pile up on the specially designed middle shelf,the hammer head will rotates in the clearance of the middle shelf,impact the big size material into small pieces,the smaller material will fall down and further impacted by the hammer heads,finally the suitable size material will be discharged through the arc-shaped grate plate on the bottom of the hammer crusher.

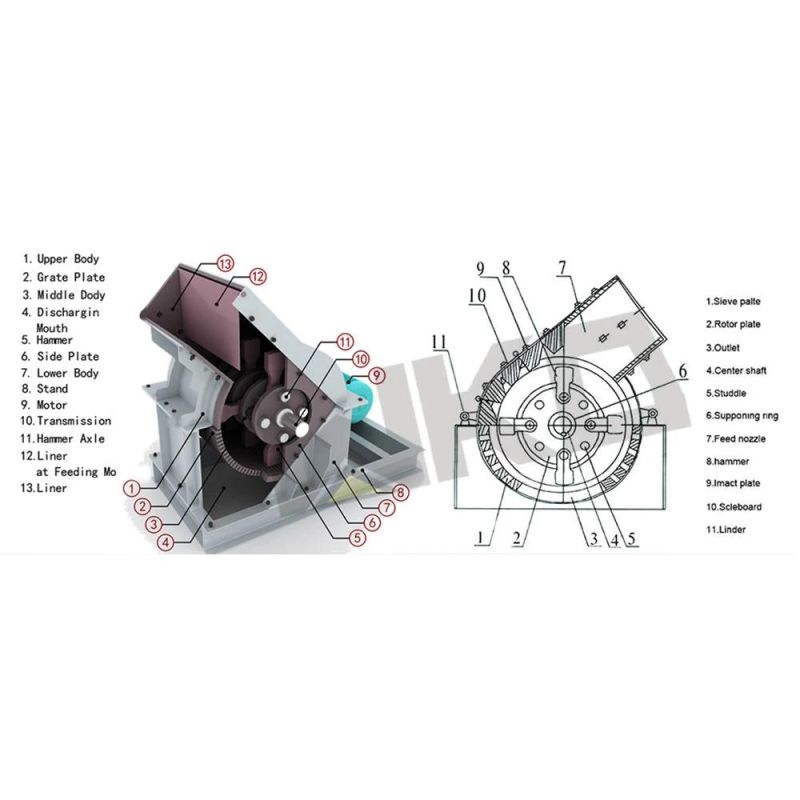

Structure

Technical Parameters

| Model (PE) | Feed size (mm) | Discharge size (mm) | Capacity (t/h) | Motor (kw) | Weight (t) |

| PC-400*300 | less than 50 | less than 20 | 5-10 | 11 | 0.8 |

| PC-600*400 | less than 120 | less than 30 | 10-22 | 22 | 2.26 |

| PC-800*600 | less than 200 | less than 35 | 18-40 | 55 | 4.8 |

| PC-1000*800 | less than 200 | less than 35 | 25-50 | 75 | 5.9 |

| PC-1000*1000 | less than 200 | less than 35 | 30-55 | 90 | 8 |

| PC-1250*1250 | less than 200 | less than 35 | 35-65 | 132 | 14 |

| PC-1400*1600 | less than 250 | less than 35 | 50-100 | 280 | 32 |

| PC-1600*1600 | less than 350 | less than 35 | 100-150 | 480 | 37.5 |

Detailed Images

Company information

Victor is a large mineral processing manufacturer for 15 years history, with covering an area of 48,000 square meters and 20,000 square meters for workshop, with various large modernized machinery facilities, professional R&D team and installation team.

With 32% market share in China and the rest to overseas, already successfully exported to over 50 countries, such as USA, England, Australia, Brazil, Turkey, Italy, Russia, South Africa, Zimbabwe, Sudan, Ghana, Congo, Morocco, India,Indonesia, Malaysia, Philippines, North Korea, Mongolia, Vietnam, Thailand etc.

Our goal is to provide one-stop service for you and assist you to solve all problems from investment to his return in the field of mining, including the preliminary mineral analysis, mineral processing test, engineering design, equipment debugging and technical training etc..

We are expert especially at mining separating and lab mining plant, main products as below:

Gold trommel wash plant

Shaking table

Spiral chute separator

Centrifugal gold concentrator

Jig separator machines

Waste recycling machine

Grinding and mill crusher

Flotation cell machine

Magnetic separator

Laboratory mining plant

Package: FCL & LCL export standard container 20GP/40GP/40HQ.

FCL: main machinery gold shaking table in nude package and bulk in container, spare parts in wooden box or as your special requirement

LCL: machinery are packed in steel frame, base and deck are separately packed.

Shipping: by sea shipment, by air shipment or by courier express, it depends on you.

Payment Terms: T/T or L/C is preferable. T/T: 30% deposit and the balance before delivery

We will take photos for your products when finished and show you before delivery. Also keep you informed for any updated information including shipping before you receive it, to let you rest assured.

Delivery time: shipped in 15 days after payment

FAQ

1.How is the quality of your products? (mining equipment/machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

2.Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we

described or the promise before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before delivery, which is international trade practice;Finished product pictures will provide to customers before delivery.

Our Service

1) Pre-sale service: Freely provide project designing, process designing, choosing suitable equipment for you.

2) Medium-sales service: Accompany you to complete the acceptance of the equipment, draft the construction scheme and detailed process, and complete process of export

3) After-sales service: Offer considerate technical guidance in installation, debugging and operators training. We are available at any time if you need.