Infrared Bridge Cutting Marble/Granite Stone Machinery (HLSQ-650) Infrared Automatic Bridge Stone Cutting Machine for Slab/Tile Cutting

Fujian Province Hualong Machinery Co., Ltd.- Warranty:1 Year

- Type:Automatic Mono Bc

Base Info

- Model NO.:HLSQ-650

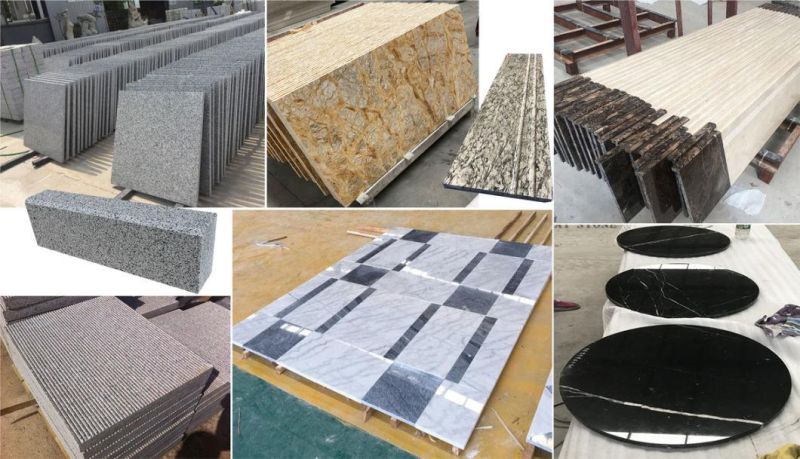

- Usage:Ceramics, Granite, Marble

- Application:Art & Craft, Stone Industry

- Source Voltage:380V

- Automation:Automatic

- Cutting Ability:High Speed

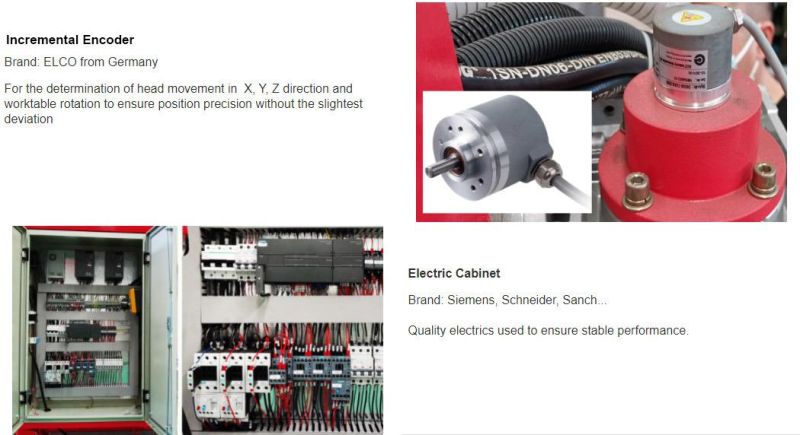

- Control:Siemens PLC

- Certification:ISO, CE

- Color:Red and Ivory

- Head Rotate 4 Positions:0,90,180,270degree

- Head Tilting Position:45,90 Degree

- Table Rotate:0-360 Degree

- Table Tilt:0-85 Degree

- Guide Rail:Hiwin Linear Guide

- Gearing:Rack Gear

- Touch Screen:Siemens

- Maximum Cutting Depth:200mm

- Main Elctric Components:Schneider and Siemens Brand

- PLC:Siemens

- Structure:Intergrated Machine

- Machine Type:Mono Bridge Saw

- Cutting:Automatically

- Remoter:with Remoter Control

- Transport Package:Plastic Packing

- Specification:Working Area: 3300*2000mm

- Trademark:Hualong

- Origin:Putian, Fujian, China

- HS Code:84641010

- Production Capacity:50 Pieces,Month

Description

Laser Reticule Apparatus

Laser Reticule ApparatusOrigin: China

Laser checking and calibration instrument to aid in lining up the cut at the beginning of processing.

Other Advantages

1) 25 years + experience professional on making stone machines.

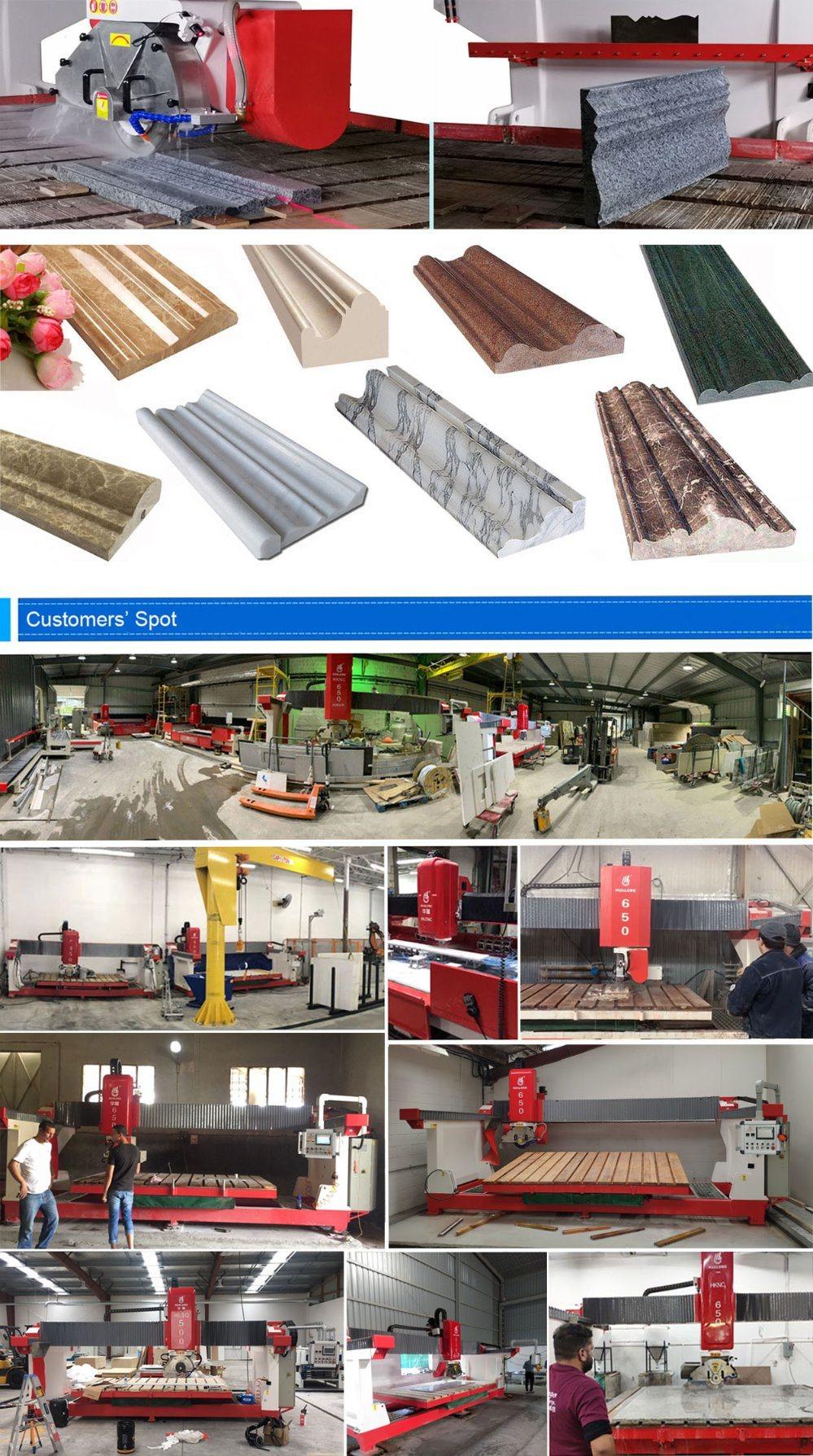

Application

* Round desktop processing

* Profiling Cutting (optional)

According to customer requirements, this machine can be equipped with profiling module to achieve profiling cutting function, used for processing special-shaped stone lines, decorating door frames, windows, columns and walls, etc.