Guide Pillar Railcar Multi-Blades Block Cutter

Shandong Datang Machinery Technology Co., Ltd.- After-sales Service:Provided

- Warranty:1 Year

- Type:CNC Cutting Machine

- Usage:Granite, Marble

- Application:Machinery & Hardware, Stone Industry

- Source Voltage:380V

Base Info

- Automation:Automatic

- Cutting Ability:High Speed

- Control:CNC

- Certification:ISO, CE

- Max Blade Diameter:1800mm

- Max Cutting Length:4800mm

- Max Cutting Width:3000mm

- Max Cutting Deepth:650mm

- Main Power:90,110kw

- Water Consumption:15m3,H

- Machine Weight:19000kg

- Overall Diamension:8500*5200*3850mm

- Processing Capacity:350-400m2,Day

- Transport Package:Nude Packing

- Specification:8500*5200*3850mm

- Trademark:datang

- Origin:China

- HS Code:8464101000

- Production Capacity:300sets,Year

Description

Basic Info.

Automation Automatic Cutting Ability High Speed Control CNC Certification ISO, CE Max Blade Diameter 1800mm Max Cutting Length 4800mm Max Cutting Width 3000mm Max Cutting Deepth 650mm Main Power 90/110kw Water Consumption 15m3/H Machine Weight 19000kg Overall Diamension 8500*5200*3850mm Processing Capacity 350-400m2/Day Transport Package Nude Packing Specification 8500*5200*3850mm Trademark datang Origin China HS Code 8464101000 Production Capacity 300sets/YearProduct Description

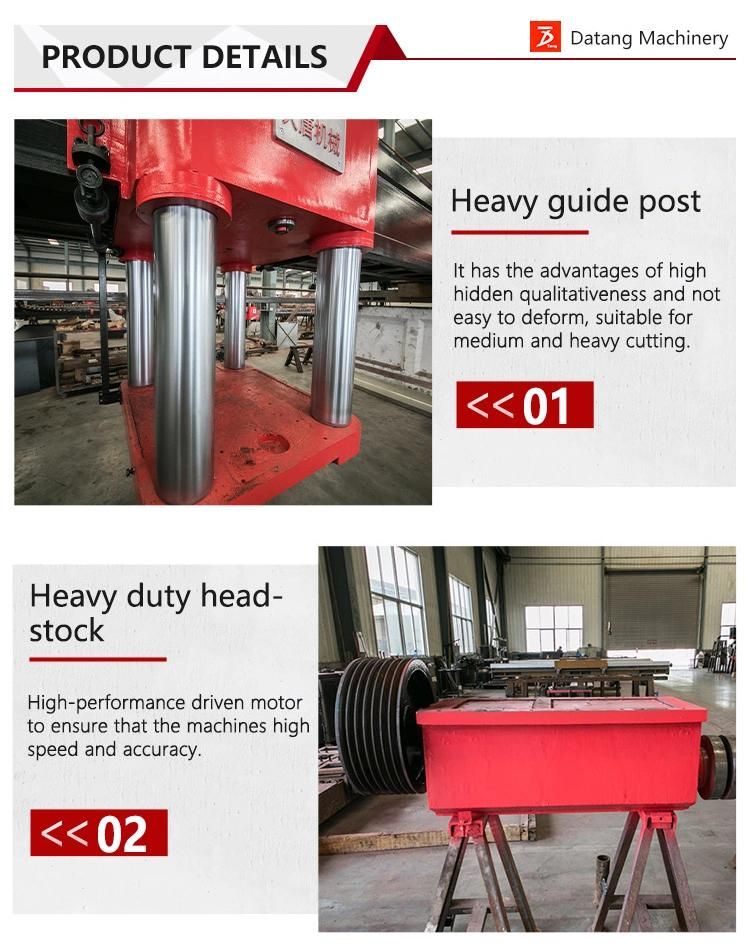

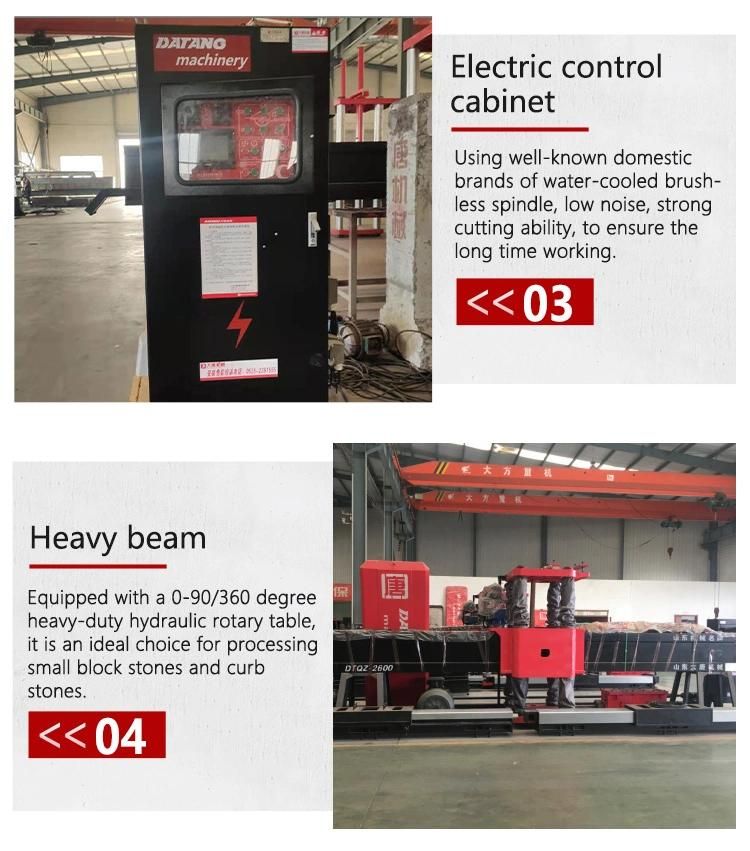

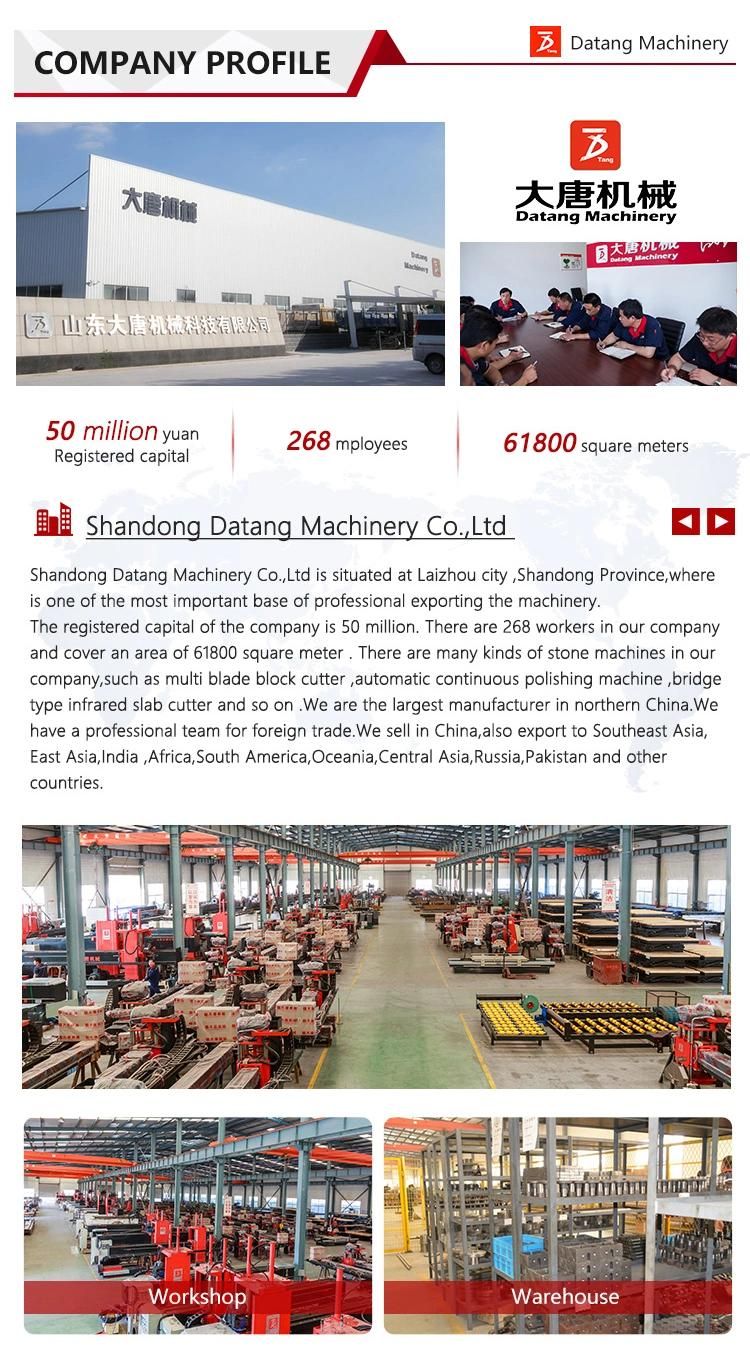

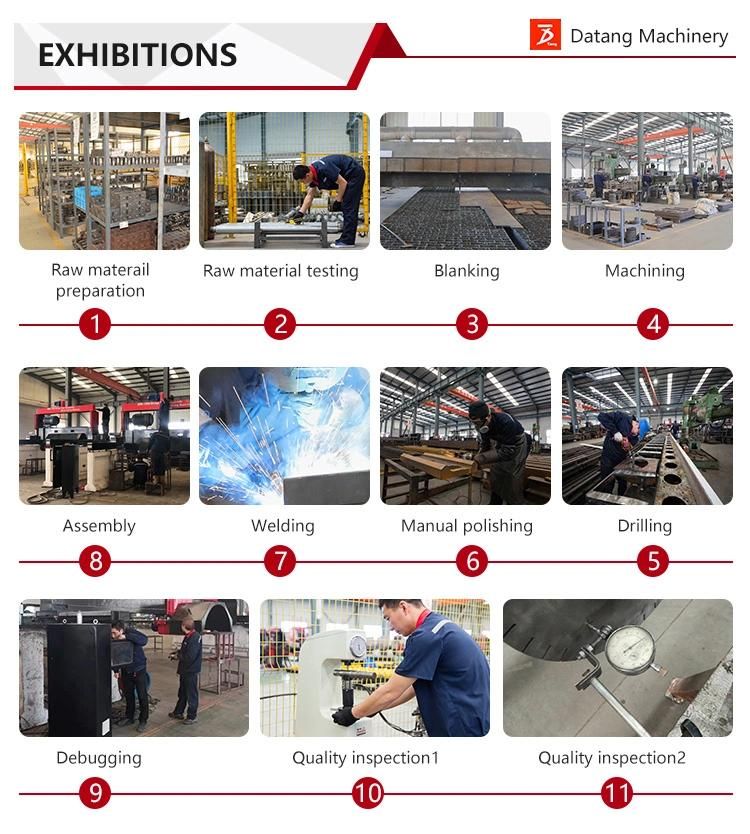

The machine adopts PLC programmable control and man-machine operation interface,suppplemented by ultra-high-precision rotary encoder for slicing, left and right blade feeding is controlled by frequency converter,which can be adjusted according to stone material.Hydrawlic lifting is asopted for up and down lifting.Combined with chrome plated guide pillar and wear-resistant guide sleeve,the clearance is small and wear-resistant and beautiful.The multi-layer seal is designed in the guide sleeve to prevent water,dust and oil leakage,so as to improve the use. High precision screw nut transmission is used for front and rear slicing ,and automatic slicing.Imported high -quality spare parts are used for key parts.The raw materials can be directlyplaced on the ground,saving the trolley and its maintenance costs;Therefore,it has the advantages of high cutting efficiency,high slicing accuracy,good flatness,high stability and easy operation.It is especially suitable for cutting high-value granite and marble blocks.Remarks:if the production process needs,users can add 360° rotary table.

| Appellation | Unit | DTQZ/MAX-1800-26P |

| Max.blade numbers: | pcs | 26 |

| Blade thickness: | mm | 4.5-5.5mm |

| Max. blade diameter: | mm | 1800 |

| Max. processing length: | mm | 4800 |

| Max. processing width: | mm | 3000 |

| Max. processing depth: | mm | 650 |

| Max. lifting stroke: | mm | 1200 |

| Water consumption | m³/h | 15 |

| Power of main motor : | kw | 90/110 |

| Total power | kw | 105/125 |

| Dimension(L*W*H): | mm | 8500*5200*3850mm |

| Weight | kg | 19000 |

Q: Are you a manufacturer or trading company?

Q: Are you a manufacturer or trading company?

A: We are the largest stone machine manufacturer in northern China.And we can provide one-stop shopping service.

Q: Can I become a distributor?

A: Yes, we have special discount for distributor.

Q: What is your competitiveness ?

A: We are the biggest stone machine manufacturer in northern China. And we can provide one-stop shopping service.Our machine has good price with best quality. Each machine has its long lifetime, high production capacity and accuracy. Also, we could appoint our engineer to come overseas to help the customer if machine got problem.

Q: When you ship my order ?

A: For the normal machines we have standard models in stock,so we can ship it as soon as we receive your payment.

If we do not have it in stock ,normally it takes 15-20days to produce after receiving deposit, but it can be negotiated if customers need urgently.

Q: How about the quality guarantee period ?

A: one year !

Q: What language does your machine have ?

A: All the machines have both Chinese and English language ,some machines also have Russian, Saudi, Polish, Korean, etc.We can make the language according to your require.If you can help to check the translation ,it will be much better.

Q: How can you guarantee the production quality ?

A: We have strictly quality control system in our production process. All products must be double checked during every manufacturing process. Requirement of customers and quality of products will be full guaranteed.We will send you the machine testing videos before shipping the machine.

Q: After I bought the machines , how I can install and operate it ?

A: We strongly suggest customer to ask our engineer to come to help you to install the machines and teach your operator how to operate and maintain it .

Q: If I don't want your engineers ,how can I install and operate the machine by myself ?