gantry mono wire saw machinery

Yunfu City Xinda Machinery Co., Ltd.- Type:CNC Cutting Machine

- Usage:Fire Brick, Red Brick, Jadestone, Cement Brick, Concrete Curb, Granite, Marble

- Application:Machinery & Hardware, Art & Craft, Construction, Stone Industry

- Source Voltage:380V

- Automation:Automatic

- Cutting Ability:High Speed

Base Info

- Model NO.:KXJ-LY-1500

- Control:CNC

- Certification:ISO, CE

- Conditiaon:New

- Container Type:40GP(DC)

- Transport Package:by Film Package

- Specification:Max cutting size: 3500× 2000× 1500mm

- Trademark:XINDA

- Origin:Yunfu City, China

- HS Code:84641090

- Production Capacity:50

Description

Basic Info.

Model NO. KXJ-LY-1500 Control CNC Certification ISO, CE Conditiaon New Container Type 40GP(DC) Transport Package by Film Package Specification Max cutting size: 3500× 2000× 1500mm Trademark XINDA Origin Yunfu City, China HS Code 84641090 Production Capacity 50Product Description

Features: the machine adopts high precision rack and gear meshing transmission to drive the left and right upright column to move synchronously instead of the traditional wire saw whose worktable is driven by screw rod. The advantage is that it overcomes the difficulties of large deformation due to the horizontal setting of the screw rod and the difficulty of processing due to the screw rod is too long, thus greatly improve the product processing accuracy and the service life of the machine, and saving the production cost of users. Meanwhile, it can extend the processing length. This advantage is unmatched by the screw driven worktable structure. This transmission feature is to fill the domestic and abroad gap of the wire saw product.The product has been authorized by the national Patent Office.Function:The machine is mainly used for processing the profile of marble and granite. Such as:processing the arc slabs of different specifications, solid columns, hollow columns, large stone lines and English letter, etc.

Brief introduction of KXJ-LY Series Wire Saw Machine:

1,the frame of the machine can move front and back,controled by servo motor.Moving on special guide rails to cut several blocks.Save much time when placing your blocks.it adopts high precision rack and gear meshing transmission to drive the left and right upright column to move synchronously instead of the traditional wire saw whose worktable is driven by screw rod. The advantage is that it overcomes the difficulties of large deformation due to the horizontal setting of the screw rod and the difficulty of processing due to the screw rod is too long, thus greatly improve the product processing accuracy and the service life of the machine, and saving the production cost of users. Meanwhile, it can extend the processing length.

2,the machine without trolley,the blocks are placed on the floor,dressing block and cut slabs by moving the frame of the machine.

3,The machine is provided with steady structure, including top beam,two upright column,square box,hydraulic tensioning unit,two big flywheel. Left side install a driven big flywheel and hydraulic tensioning device. hydraulic tensioning device controls diamond wire tension or loosen, at the same time keep the diamond wire pressure. Right side install a driving flywheel and main motor, the driving flywheel is driven by main motor with belt.it can control the speed of wire between 0-40m/s via inverter.the machine can cut different kind of stone material.

4,In order to reducing the diamond wire wear and keeping the diamond wire steady , the machine are equiped with two guide wheels (Diameter: 300mm). guide wheels are protected by rubber liners which can be easily changed once they are worn out.

5,According to the size of the stone,we equip with an electric system for bringing closer the guide wheels that is to adjust the cutting width as stone size, reducing the arch value when cutting with diamond wire .

6,the up and down screws are covered with a short platic pipe to hold the grease and be oiled. protected with dust cover against dust and water.

7,There has automatic alarm if wire broken.

8,We have a cooling system for diamond wire.it can detect water pressure.the machine will automatically stop in case of no water or insufficient water flow, to protect the diamond wire.

Technical parameters:

| Model Parameters | KXJ-LY-1500 | KXJ-LY-1800 | KXJ-LY-2200 |

| FOB shenzhen port price | 34000USD | 37000USD | 44000USD |

| Diameter of Diamond Wire | Φ8-Φ11 | Φ8-Φ11 | Φ8-Φ11 |

| Length of Diamond Wire | 18100mm | 20100mm | 22150mm |

| Speed of Wire | 0-40m/s | 0-40m/s | 0-40m/s |

| Worktable Size | NO | NO | NO |

| Range of Cutter Movement | 1600mm | 1900mm | 2200mm |

| Max Cutting Size(L×W×H) | 3500×3800×1500mm | 3600×3800×1800mm | 3600×3800×2100mm |

| Production Efficiency | 1-3m²/h(marble) 0.5-2m²/h(granite) | 1-3m²/h(marble) 0.5-2m²/h(granite) | 1-3m²/h(marble) 0.5-2m²/h(granite) |

| Main Motor Power | 11KW | 11KW | 15KW |

| Water Consumption | 3m³/hour | 3m³/hour | 3m³/hour |

| Overall Dimension | 8600×6100×4300mm | 9200×6100×5100mm | 9800×6100×5800mm |

| Total Power | 20KW | 20KW | 24KW |

| Voltage/Frequency(V/HZ) | 380V/50HZ | 380V/50HZ | 380V/50HZ |

| Total Weight | 11.6T | 13.4T | 14T |

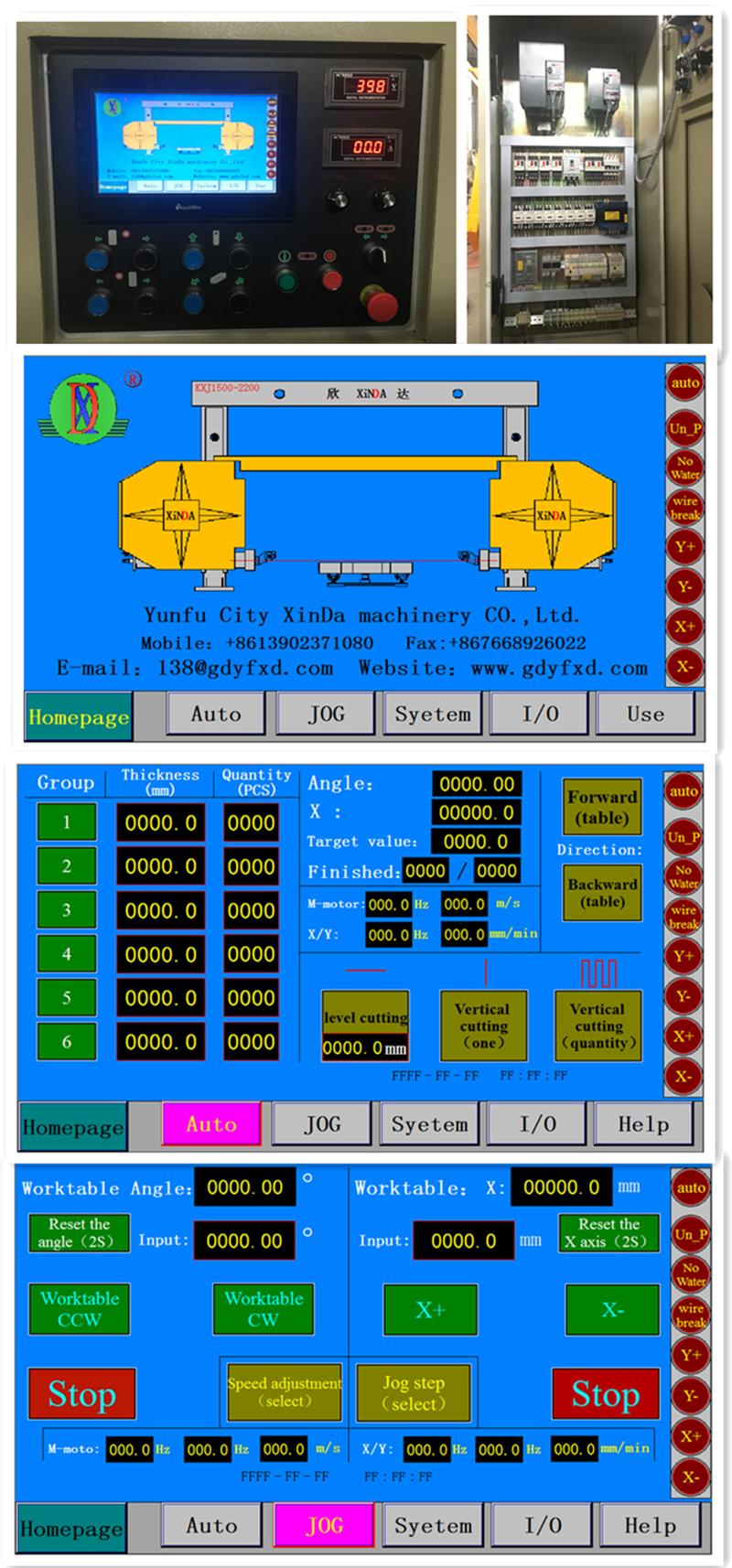

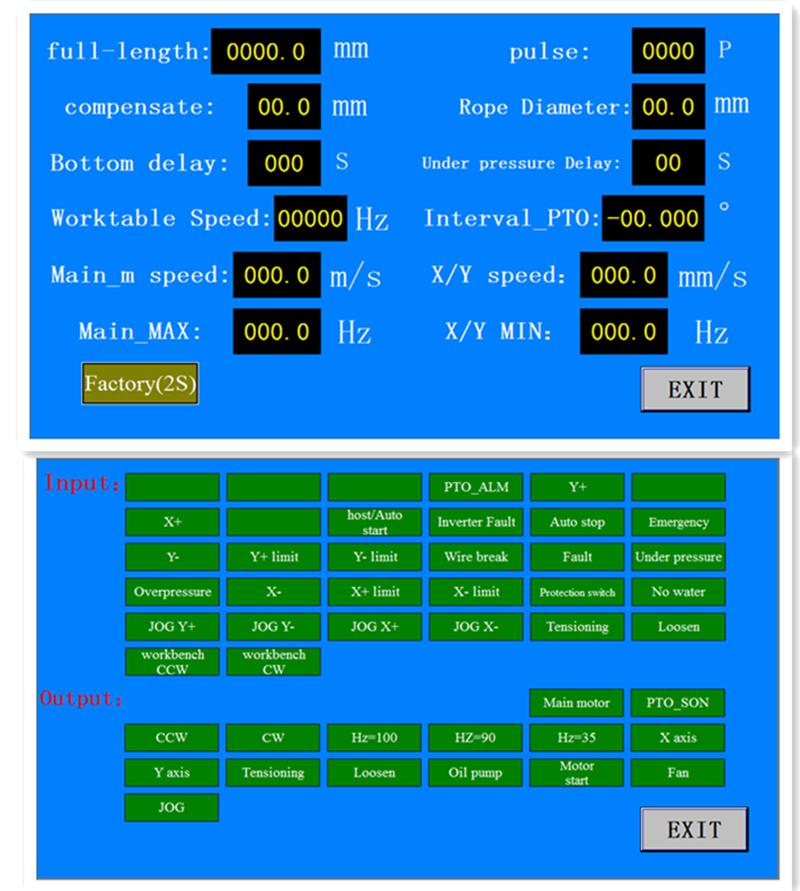

Electric Cabinet& Operation Panel Photos :

Exhibition:

FAQS:

1) Payment:

30% of total value (down payment)for placing an order, we start to produce the machine→70% (balance payment)before loading the machine to container

2) Delivery time:

The wire saw machine can be shipped within 15 weekdays when received down payment.

3) Guarantee period:

The machine is guaranteed for one year. The man-made accident and the Lightning , Flood ,earthquake , wrong voltage are not covered by the warranty.

4)How about our service?

1.Six engineers are special for installation service for oversea customer. If customer needs our installation service,we are available to dispatch any time.

2. Technical Support 24 hour on line.