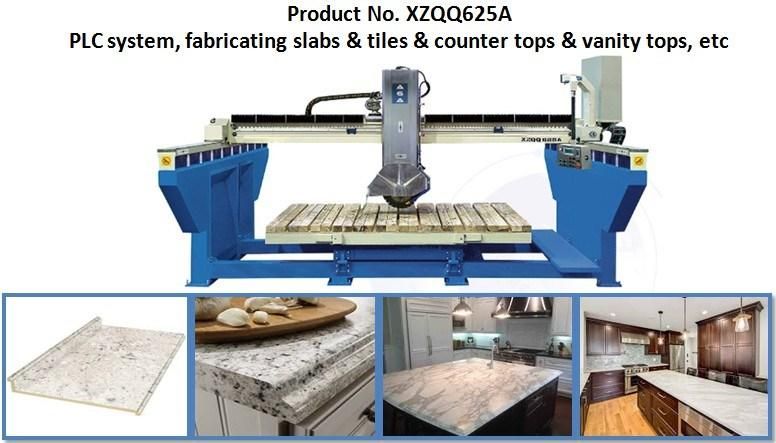

Robust CNC Machine Granite Bridge Saw Cutting Countertops Automatically (XZQQ625A)

Xiamen Aga Import and Export Co., Ltd.- After-sales Service:24 Hours on Line Services

- Warranty:1 Year Warranty

- Type:CNC Cutting Machine

- Usage:Granite, Marble, Quartz Sandstone Limestone Other Engineered Stones

- Application:Machinery & Hardware, Construction, Stone Industry

- Source Voltage:380V

Base Info

- Model NO.:XZQQ625A

- Automation:Automatic

- Cutting Ability:High Speed

- Control:CNC

- Certification:ISO, CE

- Max. Length of Cutting (Table Size):3200*2000mm

- Max. Cut Thick:170mm

- Max. Blade Size:625mm

- Tilting Table:0-85 Degree Easy for Materials Loading

- Rotation Table:0-360 Degree Stopped Any Postion

- Tilting Blade:0-45 Degree for Miter Cut

- Power of Spindle:15kw 20HP

- Repeat Cutting:99 Repeat Cutting by Program

- Transport Package:Plastic Packing

- Specification:6*5*3m

- Trademark:AGA Machinery

- Origin:Xiamen China

- HS Code:84641090

- Production Capacity:200sets,Month

Description

Basic Info.

Model NO. XZQQ625A Automation Automatic Cutting Ability High Speed Control CNC Certification ISO, CE Max. Length of Cutting (Table Size) 3200*2000mm Max. Cut Thick 170mm Max. Blade Size 625mm Tilting Table 0-85 Degree Easy for Materials Loading Rotation Table 0-360 Degree Stopped Any Postion Tilting Blade 0-45 Degree for Miter Cut Power of Spindle 15kw 20HP Repeat Cutting 99 Repeat Cutting by Program Transport Package Plastic Packing Specification 6*5*3m Trademark AGA Machinery Origin Xiamen China HS Code 84641090 Production Capacity 200sets/MonthProduct Description

Robust 5 Axis CNC Machine Granite Bridge Saw Cutting Countertops AutomaticallyMachine model: XZQQ625A

Product description of the stone bridge saw

Product description of the stone bridge saw Bridge saw XZQQ625A is infrared automatic stone bridge cutting machine applicable for cutting granite, marble, quartz and engineered stones.

Machine adopts PLC system and Human-machine interface, togethering with ultra-high precision rotary encoder positioning and infrared device, with Chinese & English double operation language, using inverter to control leftright feeding,adjusting the speed according to stone material, using hydraulic lifting system which equipted through 4 guide post, also this machine provide the unique side beam protection device, main spare parts adopt imported well-quality materials.

The whole machine is featured with high cutting efficiency, high cutting precision, high stability, easy to operate, specially high value granite and big size marble.

Key words: bridge cutting machine, stone cutting machine, bridge saw, marble cutting machine, cnc machine, etc.

Technical parameters of the stone bridge saw:

| Blade size | 400 - 625 mm 16" - 25" |

| Cut length | 3200 mm 126" |

| Cut width | 2000 mm 78.7" |

| Cut thick | 170 mm 6.7" |

| Blade tilt | 0 - 45° |

| Table rotate | 0 - 360° locked any position |

| Table tilt | 0 - 85° |

| Spindle motor | 15 Kw 20 HP |

| Size (L×W×H) | 6×5×3 m 20'×16'×9.9' |

| Weight | 7200 Kg 16,000 Lbs |

Advantages of the stone bridge saw:

The design of the machine provides the user safe and easy exploitation, high performance and productivity.

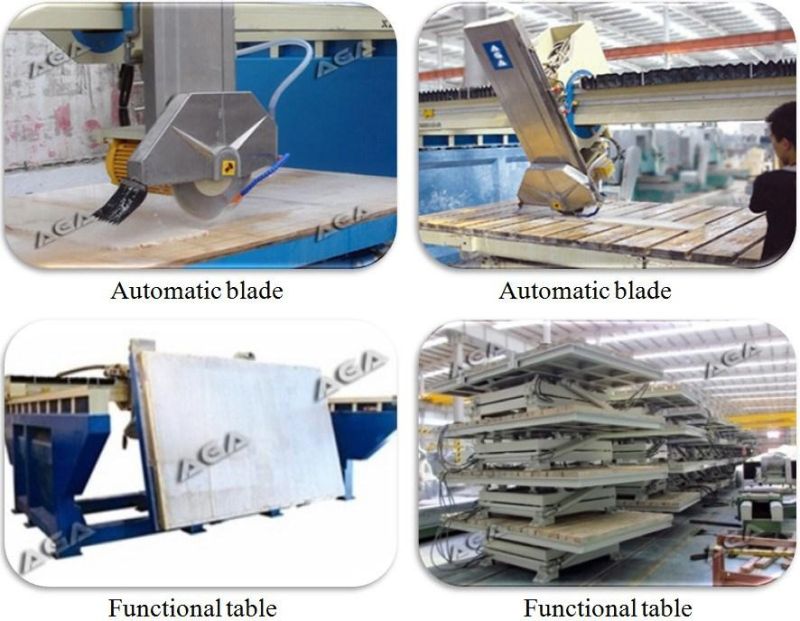

Y axis side walking group and X axis cutting movement group, control racks, pinions, linear rails and ball-bearings are working in oil pool. All moving parts are protected from water and dust by covering.

All comandulli machines are manufactured not only to perform consistently at the highest level for many years, but also to enable longevity of the machine.

The machine structure goes through a metallization process, and is finished with a special cataphoresis painting treatment allowing both a long rust free life, and great looks.

1) The tilting head of this bridge saw provides 0°-45°for miter cut very excellent performance in cutting and fabricating stones.

2) Powered table tilts 0-85 degree hydraulic for easy load of material. It rotates 0°-360° stopping automatically at 45°, 90° and any angle for changing cutting position.

3) Automated programming, electric system is very simple and easy to operate. All functions are operated on the color touch screen control panel.

4) Wireless remote provides easy control of the saw making its users very friendly.

5)Laser guide shows precision cutting every time in +/-0.2mm making beautiful slabs, tiles, counter tops, etc.

6) Automatic water control saving every drop.

7) Main structures of the granite bridge saw are made of very strong cast iron and stainless steel for protection.

FAQ:

1) Payment:

T/T in advance, we accept 30% deposit, 70% before shipment.

2) Delivery time:

The bridge saw can be shipped immediately when machine in stock; 4-5 weeks ready for shipment when machine not in stock. Time for ocean shipping depends on where you are located.

3) Shipment:

For FOB or CIF price, we will arrange shipment for you.

4) Documents after shipment:

After shipment, we will send all original documents to you by DHL or Tele-Release, including Packing List, Commercial Invoice, B/L, and other certificates as required by clients.

AGA Machinery:

AGA has been devoting to making machinery for processing and fabrication of marble granite and providing reliable service. The products include bridge saw, block cutter, polishing machine as well as equipments for other construction stones. The equipments have been successfully exported to world stone market in U.S.A, Canada, Europe, Mid East, Egypt, India, etc.

AGA understand that machinery creats value for customer and every machine comes from sophisticated technology and is manufactured by dedicated and experienced workers under strict inspection and full test. AGA insists on equipments of high quality and advanced technology to assist customers in their pursuit of a true competitive advantage. Our philosophy is all about professional entrepreneurship and perfectly serving our clients and the mission is to help customers obtain the best return on the investment. We care about customers because by choosing us you giving us a chance to make your machine more productive that also makes your products unrivaled in the competitive market and we are happy to do that professionally and passionately.