Hknc-650 5 Axis CNC Bridge Saw Marble Granite Stone Cutting Machine for Sale

Fujian Province Hualong Machinery Co., Ltd.- Usage:Ceramics, Granite, Marble

- Application:Art & Craft, Construction, Stone Industry

Base Info

- Model NO.:HKNC-650

- Source Voltage:380V

- Automation:Automatic

- Cutting Ability:High Speed

- Control:CNC

- Certification:UL, ISO, CE

- Color:Red and Ivory

- Guide Rail:Linear Guide

- Touch Screen:Italian

- Gearing:Rack Gear

- Head Rotation:0-360 Degree

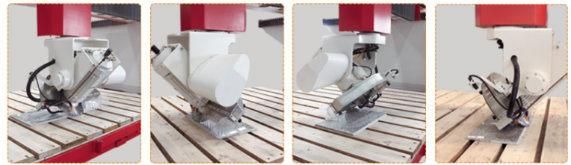

- Head Tilting:0-90 Degree

- Table Rotation:0-360 Degree

- Table Tilting:0-85 Degree

- Diameter of Saw Blade:400-600mm

- Dimension of Working Platform:3300X2000mm

- Max. Length of Horizontal Cutting:3300mm

- Max. Cutting Thickness:200mm

- Max. Lifting Travel of Cutter:280mm

- Main Motor Power:15kw

- Gross Power:21.3kw

- Transport Package:Polypropylene Plastics Packing

- Specification:6300(L)*3600(W)*3100(H)

- Trademark:Hualong

- Origin:Putian, Fujian, China

- HS Code:84641010

- Production Capacity:50 Pieces,Month

Description

Basic Info.

Model NO. HKNC-650 Source Voltage 380V Automation Automatic Cutting Ability High Speed Control CNC Certification UL, ISO, CE Color Red and Ivory Guide Rail Linear Guide Touch Screen Italian Gearing Rack Gear Head Rotation 0-360 Degree Head Tilting 0-90 Degree Table Rotation 0-360 Degree Table Tilting 0-85 Degree Diameter of Saw Blade 400-600mm Dimension of Working Platform 3300X2000mm Max. Length of Horizontal Cutting 3300mm Max. Cutting Thickness 200mm Max. Lifting Travel of Cutter 280mm Main Motor Power 15kw Gross Power 21.3kw Transport Package Polypropylene Plastics Packing Specification 6300(L)*3600(W)*3100(H) Trademark Hualong Origin Putian, Fujian, China HS Code 84641010 Production Capacity 50 Pieces/MonthProduct Description

HKNC-650 is a CNC Controlled bridge saw with 5 interpolated axes, specially engineered to cut and process the marble, granite, or other natural and engineered stones.

It is supplied with a Italian touch screen to achieve cutting and movement through the easy and intuitive use of the CNC software (Cutting CAM). The machine can implement different complex curved surface processing, and combine the functions of carving, milling, cutting, drilling into an organic whole.

The specific functions are listed as followings.

1. 0° to 360° any angle's automatic positioning cutting.

2. Linear guideway in "X, Y, Z" axis to guarantee accuracy and speed.

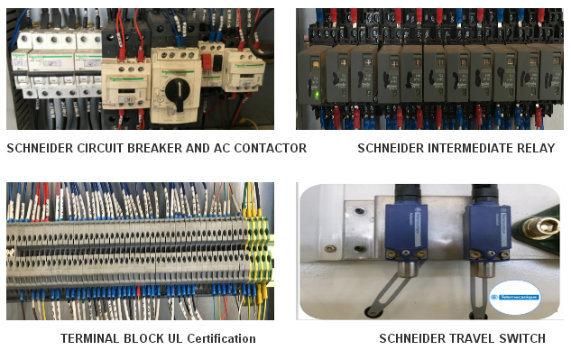

3. Electric components in international standards to be easily sourced

ITALY CPU ITALY MOTOR DRIVING SANCH FREQUENCY CONVERTER ITALY SERVO MOTOR

4. Italian imported original servo motors for 5 interpolated axes (X,Y,Z,C,A) to faciliate accurate positioning and faster cutting.

5. Italian imported original software and 15 inch industrial computer screen from Italy.

6. Italian control system in different languages for automatic cutting and easy operation, such as English, Italy, Spanish, Chinese.

7. Milling cutting

8. Engraving

9. Profiling and curved surface processing

10. Photoing

11. Safety door infrared induction (optional)

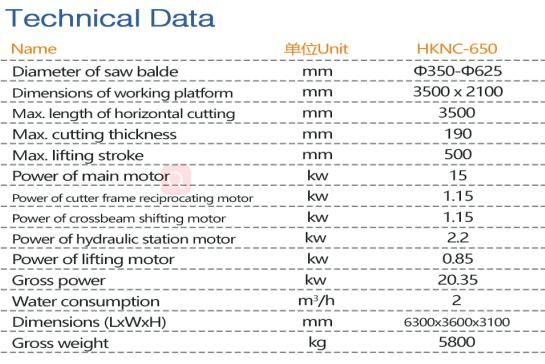

Technical data of the machine shown as below

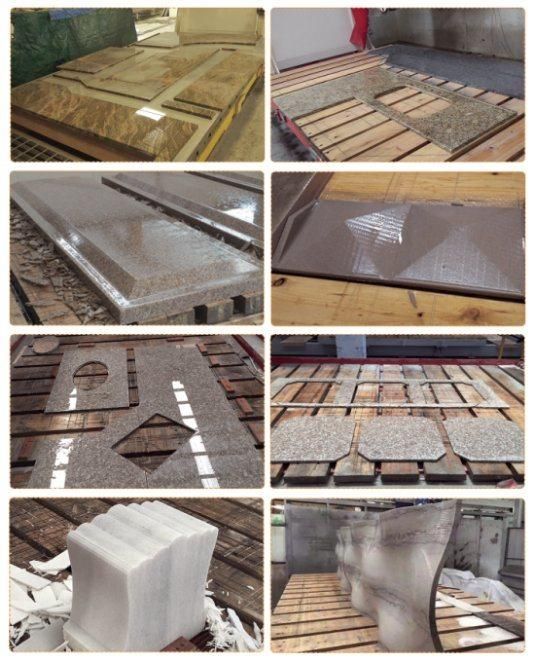

The finished products that our machine can process are shown as followings