Primary Rock Granite Stone Jaw Crusher Crusher

ZHENGZHOU YUFENG HEAVY MACHINERY CO., LTD.- After-sales Service:After Sales and Accessories Support

- Warranty:1 Year

- Type:Jaw Crusher

- Application:Machinery & Hardware, Chemical, Construction, Mineral Industry, Stone Industry

- Drive:Electric or Diesel

- Crushing Style:Squeezing

Base Info

- Model NO.:PE600*900

- Compressive Strength (For Crushing):Less Than 320MPa

- Crushing Degree:Coarse Crusher

- Certification:CE, ISO

- Condition:New

- Color:Customized

- Size of Feeding:600*900mm

- Max Feeding Size:500mm

- Adjustable Size of Discharge:65-140mm

- Capacity:60-160tph

- Motor Power:75kw

- Transport Package:Container or Wooden Cases

- Specification:100 tons per hour

- Trademark:YUFCHINA

- Origin:China

- HS Code:84741000

- Production Capacity:50 Sets Per Month

Description

Jaw Crushers are used extensively throughout the world by the aggregate, mining and recycle industries. Their large physical size and rectangular feed opening enable them to receive a larger feed size than most other types of crushers. Rugged construction, simplicity of design and the ability to crush most types of material, including hard abrasive stone, make them ideally suited for use as the primary crusher within a crushing circuit.

Below will enhance crusher capacity and performance:

1. Proper selection of the jaws.

2. Proper feed gradation.

3. Controlled feed rate.

4. Sufficient feeder capacity and width.

5. Adequate crusher discharge area.

6. Discharge conveyor sized to convey maximum crusher capacity.

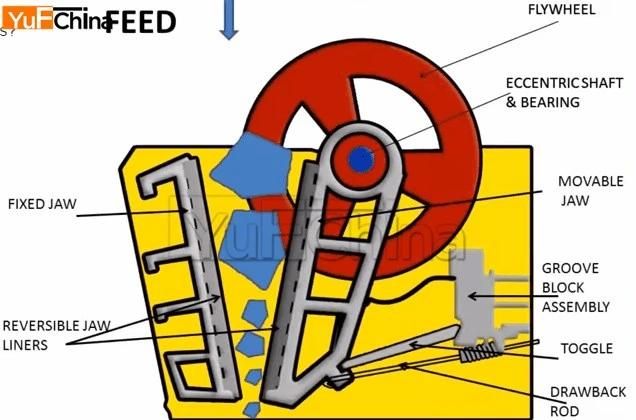

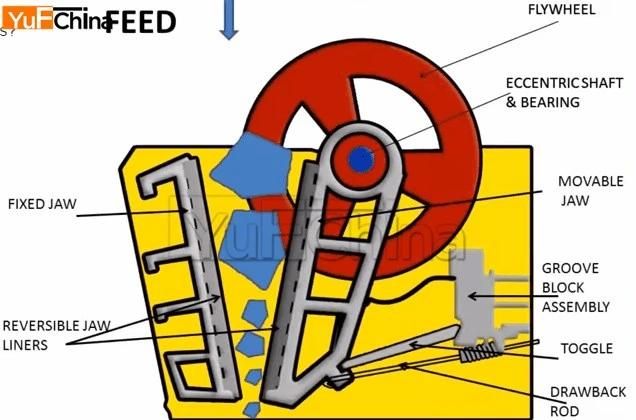

Rock crusher working principleThis style of crusher uses compression to crush rock by squeezing it between two jaws: one stationary and one movable. The movable jaw is attached to an eccentric shaft that causes it to move in a reciprocating motion. Rock enters the crushing chamber from the top and moves through the chamber, which gets narrower as it gets deeper, until it is caught between the two jaws, where it is squeezed until it fractures.

The jaw crusher discharge opening is the distance from the valley between corrugations on one jaw to the top of the mating corrugation on the other jaw. The crusher discharge opening governs the size of finished material produced by the crusher.

Stone crusher application

Stone Crushing

Concrete Crushing

Asphalt Crushing

Ore Crushing

Jaw crusher and Advantages

1. High efficiency and low operation cost

2. Flexible capacity

3. Simple structure and easy to operate

4. Over loading protection

5. Easy replacement of wearing parts

6. Long service life

7. High reliability

8. Wide ranges of choices

9. Alternative ordinary and hydraulic types

Jaw crusher working site photos

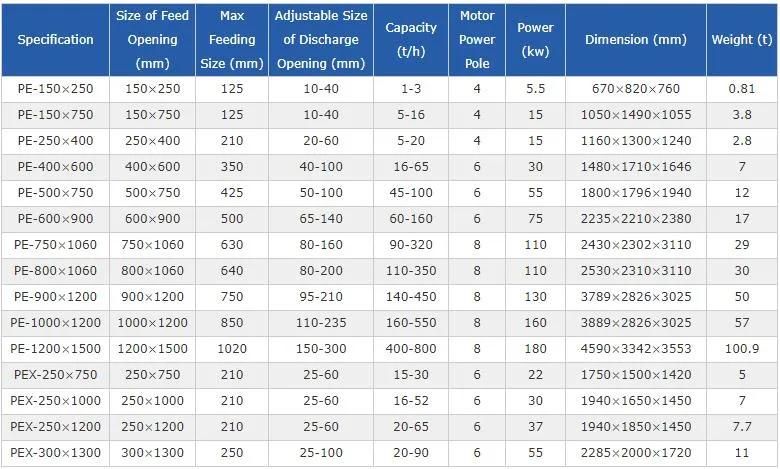

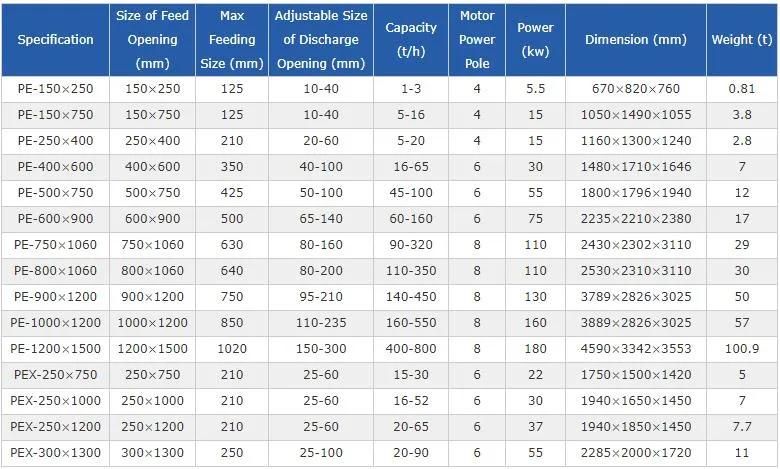

Jaw crusher technical data

Our Services

Pre-sale

1. Depending on customer's requirement, we insist on "making profit at lowest investment" and gives best solution as per the customer's special demand.

2. Design the most reasonable project and maximum customers' profit.

3.Provide engineers to scene to plan work site if the customer needed.

4. Provide equipment list, design drawing, construction drawing, equipment install drawing.

After Sale's Service:

a.1 year warranty ,if the machine break is by quality detect not personal reason or natural disaster ;

c. Easy break spare parts not include .Engineer installation abroad and teach you master the skill to produce wood pellet;

c. Supply you the spare parts with favorable price all the machine life time;

d. Caring service, carefully manufacture and desirable price make customers at ease.

Below will enhance crusher capacity and performance:

1. Proper selection of the jaws.

2. Proper feed gradation.

3. Controlled feed rate.

4. Sufficient feeder capacity and width.

5. Adequate crusher discharge area.

6. Discharge conveyor sized to convey maximum crusher capacity.

Rock crusher working principleThis style of crusher uses compression to crush rock by squeezing it between two jaws: one stationary and one movable. The movable jaw is attached to an eccentric shaft that causes it to move in a reciprocating motion. Rock enters the crushing chamber from the top and moves through the chamber, which gets narrower as it gets deeper, until it is caught between the two jaws, where it is squeezed until it fractures.

The jaw crusher discharge opening is the distance from the valley between corrugations on one jaw to the top of the mating corrugation on the other jaw. The crusher discharge opening governs the size of finished material produced by the crusher.

Stone crusher application

Stone Crushing

Concrete Crushing

Asphalt Crushing

Ore Crushing

Jaw crusher and Advantages

1. High efficiency and low operation cost

2. Flexible capacity

3. Simple structure and easy to operate

4. Over loading protection

5. Easy replacement of wearing parts

6. Long service life

7. High reliability

8. Wide ranges of choices

9. Alternative ordinary and hydraulic types

Jaw crusher working site photos

Jaw crusher technical data

Our Services

Pre-sale

1. Depending on customer's requirement, we insist on "making profit at lowest investment" and gives best solution as per the customer's special demand.

2. Design the most reasonable project and maximum customers' profit.

3.Provide engineers to scene to plan work site if the customer needed.

4. Provide equipment list, design drawing, construction drawing, equipment install drawing.

After Sale's Service:

a.1 year warranty ,if the machine break is by quality detect not personal reason or natural disaster ;

c. Easy break spare parts not include .Engineer installation abroad and teach you master the skill to produce wood pellet;

c. Supply you the spare parts with favorable price all the machine life time;

d. Caring service, carefully manufacture and desirable price make customers at ease.