PE Jaw Crusher Machine/ Jaw Crusher Machine Price

Shanghai Zenith Mineral Co., Ltd.- Type:Jaw Crusher

- Application:Construction, Mineral Industry, Stone Industry

- Drive:Electric

- Crushing Style:Grinding & Impact

- Compressive Strength (For Crushing):>300MPA

- Crushing Degree:Coarse Crusher

Base Info

- Model NO.:PE series

- Finished Surface:Hole Process

- Certification:CE, ISO, GOST

- Condition:New

- Color:Iron Grey

- Spare Parts Supply:for Whole Year

- After-Sale Service:for Whole Using Year

- Test&Installation:Engineer Assigned

- Export Markets:Global

- Transport Package:Container, Nude Packs, in Bulk

- Specification:ISO9001: 2000

- Trademark:Zenith

- Origin:China

- HS Code:8474209000

- Production Capacity:40-850tph

Description

Basic Info.

Model NO. PE series Finished Surface Hole Process Certification CE, ISO, GOST Condition New Color Iron Grey Spare Parts Supply for Whole Year After-Sale Service for Whole Using Year Test&Installation Engineer Assigned Export Markets Global Transport Package Container, Nude Packs, in Bulk Specification ISO9001: 2000 Trademark Zenith Origin China HS Code 8474209000 Production Capacity 40-850tphProduct Description

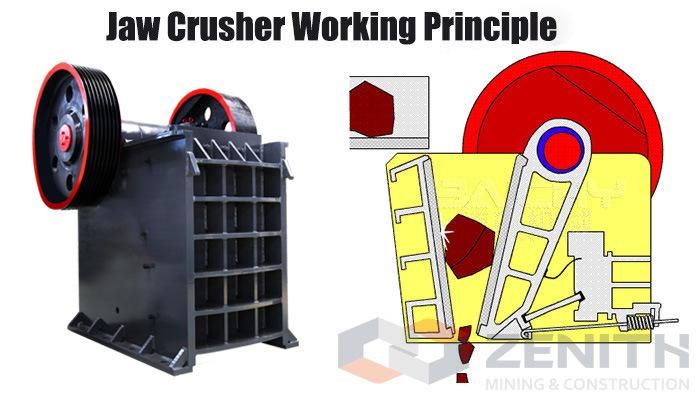

Jaw crusher machine:The Zenith Jaw Crusher are ideally suitable for primary and secondary crushing, with low power consumption and easy maintenance. Every feature of jaw crushers has been carefully designed to provide superior quality and performance. The jaw crushers are widely used for crushing various materials like stone, granite, trap rock, coke, coal, manganese ore, iron ore, emery, fused aluminum, oxide, fused calcium carbide, lime stone, quartzite, alloys, etc. Jaw crushers are recommended by leading consultants in this field and are used by hundreds of customers all over the world.

Features of jaw crusher machinery:

1.Manufacturing technique is of world class;2.The movable jaw assembly is of more advanced technology. It adopts high quality welding technology, and the eccentric shaft is elaborate;3.Integral cast steel structure is adopted for bearing seat to ensure the complete match with the frame;4.Finite Element Analysis is adopted to strengthen the crusher;5.The crushing chamber adopts "V" shape structure, which makes the feeding port's actual width be in accordance with the nominal.6.Discharging port adjustment is quicker and more convenient. Wedge block adjustment device is easier, safer and faster.7.Larger and more wearable main bearing is used to lengthen the service life; The bearing capacity is higher and effective labyrinth seal also lengthens the lifespan.8.The teeth protection plate increases the length of jaw plate.

Application of Jaw Crusher:1) Jaw Crusher is widely used in the works of mine, smelting, building materials, road, railway, irrigation,chemical industry etc.2)The crusher is applicable for the rough and medium crushing of rocks and ores with a compressive strength less than 320MPA. It is the preferred equipment of secondary crushing.

Application of Jaw Crusher:1) Jaw Crusher is widely used in the works of mine, smelting, building materials, road, railway, irrigation,chemical industry etc.2)The crusher is applicable for the rough and medium crushing of rocks and ores with a compressive strength less than 320MPA. It is the preferred equipment of secondary crushing.

Jaw crusher machiner parameters:

| Model | Feeder Opening (mm) | Setting Adjustment Range (mm) | Max. Feeding Size (mm) | Capacity (t/h) | Motor Power (KW) | Weight (t) | Overall Dimension (mm) |

| PE500x750 | 500x750 | 50-100 | 425 | 40-110 | 45-55 | 12 | 2035x1921x2000 |

| PE600x900 | 600x900 | 65-160 | 480 | 90-180 | 55-75 | 17 | 2290x2206x2370 |

| PE750x1060 | 750x1060 | 80-140 | 630 | 110-320 | 90-110 | 29 | 2655× 2302× 3110 |

| PE900x1200 | 900x1200 | 95-165 | 750 | 220-450 | 110-132 | 52 | 3200× 3050× 2950 |

| PE1000x1200 | 1000x1200 | 195-265 | 850 | 315-550 | 110-132 | 57 | 3800× 3166× 3045 |

| PE1200x1500 | 1200x1500 | 150-300 | 950 | 400-850 | 220 | 82.5 | 4200× 3750× 3820 |