High Performance Stone Jaw Crushing Plant with Capacity 100-200tph

Shanghai Zenith Mineral Co., Ltd.- Warranty:12 Months

- Type:Jaw Crusher

Base Info

- Model NO.:PEW250x1200, PEW400x600, PEW760, PEW860

- Application:Construction, Mineral Industry, Stone Industry

- Drive:Hydraulic

- Crushing Style:Extruding & Milling

- Compressive Strength (For Crushing):>300MPA

- Crushing Degree:Coarse Crusher

- Finished Surface:Hole Process

- Certification:CE

- Condition:New

- Color:Iron Grey

- Spare Parts Supply:for Whole Year

- After-Sale Service:for Whole Using Life

- Test&Installation:Engineer Assigned

- Export Markets:Global

- Transport Package:Container, Nude Packs, in Bulk

- Specification:ISO9001: 2000

- Trademark:Zenith

- Origin:Shanghai Zenith, China

- HS Code:8474209000

- Production Capacity:40-850tph

- Package size per unit product:500.00cm * 300.00cm * 400.00cm

- Gross weight per unit product:10000.000kg

Description

Basic Info.

Model NO. PEW250x1200, PEW400x600, PEW760, PEW860 Application Construction, Mineral Industry, Stone Industry Drive Hydraulic Crushing Style Extruding & Milling Compressive Strength (For Crushing) >300MPA Crushing Degree Coarse Crusher Finished Surface Hole Process Certification CE Condition New Color Iron Grey Spare Parts Supply for Whole Year After-Sale Service for Whole Using Life Test&Installation Engineer Assigned Export Markets Global Transport Package Container, Nude Packs, in Bulk Specification ISO9001: 2000 Trademark Zenith Origin Shanghai Zenith, China HS Code 8474209000 Production Capacity 40-850tphPackaging & Delivery

Package size per unit product 500.00cm * 300.00cm * 400.00cm Gross weight per unit product 10000.000kgProduct Description

High performance stone jaw crushing plant with capacity 100-200tph

stone jaw crushing plant introduction

stone jaw crushing plant can reach the crushing ratio of 4-6 and the shape of final product is even. It is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc. The pressure resistance strength is under 200Mpa, that is, suitable for primary crush. Jaw crusher can be used in mining, metallurgical industry, construction, road and railway building, conversancy, chemistry, etc.

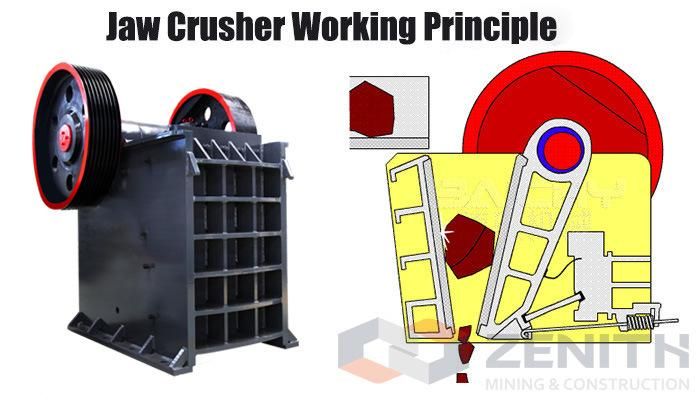

stone jaw crushing plant Structures and working principle:

The structure of jaw crusher contains the frame, eccentric shaft, big belt pulley, flywheel, movable jaw, side guard plate, toggle plate, rear seat of toggle plate, modulation gap screw, returning spring, fixed jaw plate and movable jaw plate, etc, among which the toggle plate is used for safety. The working mode of this series jaw crusher is pressing deviously.

This stone jaw crushing plant working theory is: The motor drives belt and belt wheel, the eccentric shaft causes the movable jaw to move down and up, forward and backward, the angle between toggle plate and movable jaw becomes bigger when the movable jaw moves up, so that the movable jaw moves toward the fixed jaw, and the materials are pressed, crushed, or cut, as a result, the aim of crushing is accomplished.

Application of stone jaw crushing plant 1.widely applied in mining, road&railway, concrete, chemical and building material industries.2.Ores and rocks with various hardness3.Concrete basis and steel structure basis4.Stationary, half-mobile and mobile applications

Main Advantages of stone jaw crushing plant 1. The stone jaw crushing plant has a deep crushing cavity and the frame employs the joggle joint welding and entirely annealing technology which make the crusher a simple, durable and robust structure and improve the capability and the crushing ratio.2.Digital simulation of the operating trace and speed of the movable jaw ensure a high capacity and low consumption rate of the ware parts.3.Utilization rate of the tooth plate has been increased by using segmented tooth plates which are replaceable.4.Hydraulic adjustment of the discharge opening ensures a more convenient and safe operation.5.The service life of the toggle plate and adjustment seat has been developed by the double-layer adjustment seat with arc-shape liner inside it which will disperse the partial pressure evenly.6.The frame could be taken into upper part and lower part which can be fixed together again by dowel pins. This sort of structure makes users easy to assembly, disassembly, transport and install the crusher.7.The stone jaw crushing plant employ the American technology. stone jaw crushing plant technical data :

Main Advantages of stone jaw crushing plant 1. The stone jaw crushing plant has a deep crushing cavity and the frame employs the joggle joint welding and entirely annealing technology which make the crusher a simple, durable and robust structure and improve the capability and the crushing ratio.2.Digital simulation of the operating trace and speed of the movable jaw ensure a high capacity and low consumption rate of the ware parts.3.Utilization rate of the tooth plate has been increased by using segmented tooth plates which are replaceable.4.Hydraulic adjustment of the discharge opening ensures a more convenient and safe operation.5.The service life of the toggle plate and adjustment seat has been developed by the double-layer adjustment seat with arc-shape liner inside it which will disperse the partial pressure evenly.6.The frame could be taken into upper part and lower part which can be fixed together again by dowel pins. This sort of structure makes users easy to assembly, disassembly, transport and install the crusher.7.The stone jaw crushing plant employ the American technology. stone jaw crushing plant technical data :| Model | Feed Opening (mm) | Max Feeding (mm) | Discharge Opening (mm) | Capacity (t/h) | REV (r/min) | Power (kw) | Motor Model | Machine Size (mm) |

| PEW250×1000 | 250×1000 | 220 | 20-40 | 15-50 | 330 | 6-37 | Y250M-6/37 | 1400×1850×1310 |

| PEW250×1200 | 250×1200 | 220 | 20-40 | 20-50 | 330 | 6-37 | Y250M-6/37 | 1400×2050×1310 |

| PEW400×600 | 400×600 | 350 | 35-85 | 15-70 | 250 | 6-37 | Y250M-6/37 | 1920×1460×1840 |

| PEW760 | 760×1100 | 620 | 75-200 | 150-350 | 270 | 6-110 | Y315L1-6/110 | 2600×2500×2200 |

| PEW860 | 860×1100 | 720 | 100-225 | 200-500 | 240 | 6-132 | Y315L2-6/132 | 3300×2320×3120 |

| PEW1100 | 1100×1200 | 930 | 150-275 | 300-650 | 210 | 8-185 | Y355L1-8/185 | 4140×2660×3560 |