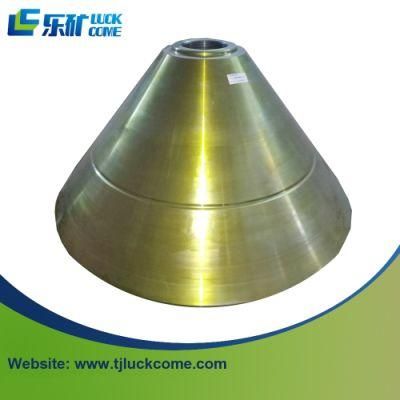

Head Assembly for Cone Crusher HP300

Tianjin Luckcome Mechanical Equipment Manufacturing Co., Ltd.- After-sales Service:Availably

- Warranty:Lifelong

- Type:Cone Crusher

- Application:Machinery & Hardware, Construction, Stone Industry

- Drive:Hydraulic

- Crushing Style:Impact

Base Info

- Model NO.:ZT-7082404300

- Compressive Strength (For Crushing):<100MPA

- Crushing Degree:Intermediate Crusher

- Finished Surface:Outer Surface Process

- Certification:CE, ISO

- Condition:New

- Color:Iron Grey

- Mining Wear Parts:Head Assembly

- OEM:New

- Transport Package:International Standard Package

- Specification:7082404300

- Trademark:LUCKCOME

- Origin:China

- HS Code:8474209000

- Production Capacity:10 PC,Month

Description

Basic Info.

Model NO. ZT-7082404300 Compressive Strength (For Crushing) <100MPA Crushing Degree Intermediate Crusher Finished Surface Outer Surface Process Certification CE, ISO Condition New Color Iron Grey Mining Wear Parts Head Assembly OEM New Transport Package International Standard Package Specification 7082404300 Trademark LUCKCOME Origin China HS Code 8474209000 Production Capacity 10 PC/MonthProduct Description

The HP Cone Crusher Series stemmed from the roots of the Symons and Omnicone lines. Luckcome followed along to meet the new demands for replacement parts for these modern crushing units. Luckcome carries the premium replacement parts for your unit. In most cases, we have the part on the shelf and ready for immediate shipment. In some cases, Luckcome has even improved the conventional design of the part to enhance durability and performance. Whether you need to replace the hydraulic cylinders, the feed plate or the eccentric ^Luckcome has your HP Crusher Parts needs covered.

Luckcome is Your SuperStore for HP Crusher Parts! All Luckcome Replacement Parts are backed by our F3 Guarantee and are shipped only after meeting our rigorous quality standards. We are committed to meeting your replacement parts need in a professional and efficient manner. Our Customer Support Department is ready to help you with a quote, to check inventory or to simply answer a technical question. Talk to your Luckcome professional today about your specific needs!

The Picture of Our store

The Picture of History Exhibition

The Picture of our Processing Machine

| Tianjin Luckcome provides professional service for improving the reliability as well as productivity of users's production. |

| Periodic inspection |

| Our experience indicates that mechanical and electrical failures usually affect the utilization and produtivity of crushing equipment directly. Therefore, Luckcome's periodic inspection is conducive to reducing the accurrence of mechanical and electrical failures, and achieving users' production target in quality, quantity and time. |

| Worn parts replacement |

| The service of worn parts replacement includes the delivery as well as replacement of worn parts, and inspection of crushing equipment. Except for replacing worn parts safely and effectively, our professional technicians also can accurately evaluate the operation and wear parts condition of crushing equipment. |

| Maintenance |

| The skillful technicians and advanced technology in our repair workshop will provide extensive maintenance service ranging from replacing bearings to renovating complete equiment. |

| Training |

| Luckcome's training service emphasizes on operation process, maintenance procedure and repair method of crushing equipment so as to enable staffs of operation, maintenance and repair to fully master technical key points and keep normal operation of equipment. |

| Process optimization and performance improvement |

| We help users select the best method for equipment operation and maintenance. In addition, Luckcome's experts can provide users with optimized suggestions, such as cavity modification and existing equipment upgrading. The purpose of performance improvement service is to help users achieve expected performance value and business target. |

| Equipment operation |

| Luckcome also can provide equipment operation service. Our engineers will assist users in completing plan compilation, equipment monitoring, operation support, repair and maintenance on users'site |