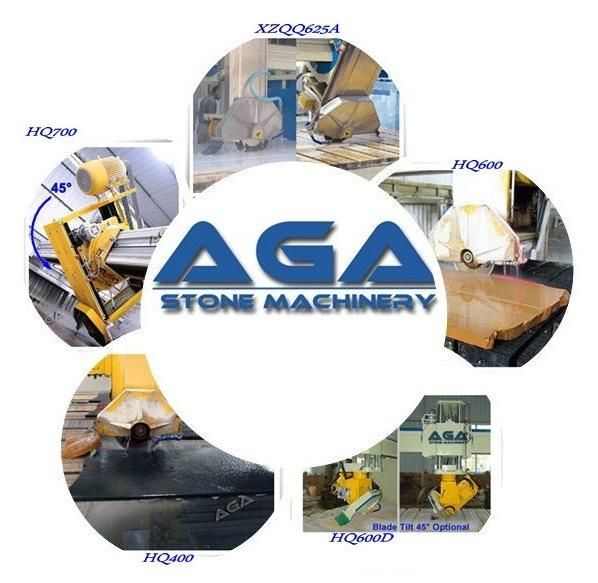

Infrared Stone Edge Cutting and Polishing Machine for Granite Quartz Diamond Cutter Price (HQ400/600/700)

Xiamen Aga Import and Export Co., Ltd.- After-sales Service:1 Year

- Warranty:1 Year

- Type:CNC Cutting Machine

- Usage:Granite, Marble

- Application:Stone Industry

- Source Voltage:380V

Base Info

- Model NO.:HQ400,600,700

- Automation:Automatic

- Cutting Ability:High Speed

- Control:CNC

- Certification:ISO, CE

- Max. Cut Size (Lxw):3200X2000 mm

- Max. Cut Thick:230 mm

- Table Tilting:0-85°

- Table Rotation:0-360°

- Blade Tilting:0-45°

- Max. Blade Size:700 mm

- Spindle Motor:18.5 Kw

- Weight:7500kg

- Transport Package:Plastic Packing

- Specification:Dimention: 6 x 5.8 x 3.5 m

- Trademark:AGA

- Origin:Xiamen, Fujian, China

- HS Code:84641010

- Production Capacity:100sets,Month

Description

Product Description

1. The bridge type infrared stone cutter is operated by computer so that it work automatically.

2. The parts and accessories of which are made of high quality steel.

3. The lifting moving driving by four lead pillars.

4. The electronic controling cabinet compries.The machine adopt PLC controlling system,variable-frequency drive(VFD) which can provide fine speed regulation,infrared checking and calibration instrument,touching operating system.

5. The computer automatic control ensures the accuracy of cutting;So,the machine endowed with high steadiness,effective and simplein operating characters.

6. Long working life, very durable.

7. Small noise, working well.

8. Better slab quantity and precision.

9. Large capacity, save energy and cost.

10. Equipped with frequency transducer and OMROM PLC, programmable and fully automatic.

11. Table tilts up to 85 degree to load the big slabs easily and it also rotates 90 / 360 degree to change the cutting position.

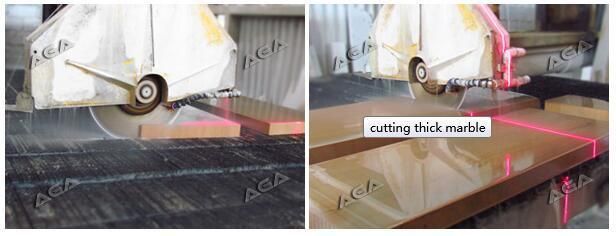

12. Touch screen operation is simple and Laser guide shows the cutting position that makes the cutting easier.

13. Machine head tilting 45 degree for miter cutting is optional.

Advantage

1. Long brigde structure for cutting big slab.

2. Tilting table for easy load of big slab.

3. Automatic cut by program on PLC system.

4. Precise movements on X, Y, Z axis ensuring cutting accuracy +/-0.2mm.

5. Electric parts from Japan for stability and long service time.

6. Main parts made of cast iron for heavy duty work and stable performance.

Specification:

| Modle | HQ400 | HQ00 | HQ700 | |

| Max. cut size ( L*W ) | mm | 3200 x 2000 | 3200 x 2000 | 3200 x 2000 |

| Max. cut thick | mm | 80 | 180 | 230 |

| Table tilting | mm | 0-85 | 0-85 | 0-85 |

| Table size ( L*W ) | ° | 3200 x 2000 | 3200 x 2000 | 3200 x 2000 |

| Table rotation | ° | 90 | 90/360 | 360 |

| Max. blade size | mm | Φ400 | Φ600 | Φ700 |

| Spindle motor | Kw | 15 | 15 | 18.5 |

| Dimention ( L*W*H ) | m | 6 x 4.8 x 2.9 | 6 x 4.8 x 3 | 6 x 5.8 x 3.5 |

Packing keywords: Diamond Cutting Machine, Edge Cutting Machine, Stone Cutting Machine, Tile Cutter, Stone Polishing Machine, Diamond Bridge Saw, Countertop Cutting Machine for Granite Marble Quartz

keywords: Diamond Cutting Machine, Edge Cutting Machine, Stone Cutting Machine, Tile Cutter, Stone Polishing Machine, Diamond Bridge Saw, Countertop Cutting Machine for Granite Marble Quartz

Related bridge saw

FAQ

1. How to pay to you?

T/T is advance we accept 30% deposit, 70% before shipment

2. How long is the delivery time?

For standard machines, it would be 2-5 weeks; For non-standard machines and customized machines according to client's specific requirements, it would be 10 days longer.

3. Do you arrange shipment for the machines?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you.

4. How about the documents after shipment?

After shipment, we will send all original documents to you by DHL or Tele-Release, including Packing List, Commercial Invoice, B/L, and other certificates as required by clients.

5. What is the packing?

a. Water-proof plastic film package with foam protection in each corner

b. Solid Seaworthy Wood Box Package

c. Save space as much as Possible for container loading.

About us:

AGA has been devoting to making machinery for processing and fabrication of marble granite and providing reliable. The products include bridge saw, block cutter, polishing machine as well as equipments for other construction stones. The equipments have been successfully exported to world stone market in USA, Canada, Europe, MID east, Egypt, India, etc.

For more details information, please visit our website: agastonemachine.en.made-in-china.com or agastonemachine.en.made-in-china.com , thanks !