Granite Crusher Plant Stone Crushing Line Price

ZHENGZHOU YUFENG HEAVY MACHINERY CO., LTD.- Type:Stone Crushing Line

- Drive:Electric

- Crushing Style:Grinding & Impact

- Crushing Degree:Ultra-Fine Mill

- Finished Surface:Outer Surface Process

- Certification:CE, ISO

Base Info

- Condition:New

- Color:Customised

- Trademark:YUFCHINA

- Origin:Henan China

- Production Capacity:50-500

Description

Features

Smart structure to save the space and reduce the site area of the project.

The basement of the plant is smaller and can be set up quicker.

All the units are assembled in the factory, so it can shorten the installation time at working site.

The coordination of the plant is harmonious and high efficiency.

Easy installation and quick maintenance.

The crushing and screening plant is easy to disassemble and reinstall, all it can ensure that the machine can be moved and combined quickly according to the requirements of the project.

All the standard crushing and screening plant can be shipped in standard containers.

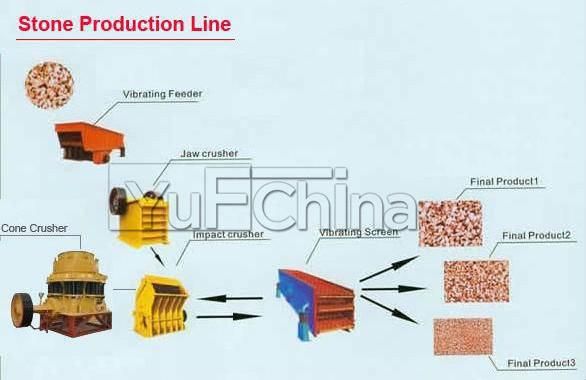

Process of the stone crushing line

Big size stones are transferred to primary crusher through vibrating feeder from hopper for first crushing, then the crushed materials are transferred to impact crusher through belt conveyor for secondary crushing. The materials crushed will be transferred to the vibrating screen, and separated to different sizes. The aggregate with suitable size will be transferred to the final product pile and aggregate with unsuitable size will be transferred to the impact crusher for re-crushing. This forms a closed and manifold cycles. The sizes of final products will be graded and separated according to customers' requirements, and the duster will be attached for the sake of environment protection.

Stone Production Line is usually decided by several factors

1) Raw materials to be crushed.

2) The hardness, percentage of Si, moisture percentage of the raw materials.

3) The average size of the raw materials before entering into the crushing system.

4) Requested product sizes, percentage of the sizes, and their usage.

5) Crushing capacity per hour for this whole line.

Features of the Stone Making Production Line

The whole line (Stone Crusher Line) is highly automatic and the size of the finished products is even, good-shaped and can be adjustable, with high crushing ratio, low power consumption and high capacity, which is suitable for big, middle and small projects, such as road and bridge construction.

How to crush the granite with high efficiency?

Crush granite Not suitable use principle of "iron hitting stone", if use hammer crusher to crush it, Only to cause destruction to both sides internecine.the life of the hammer head and mechanical are not long. use intergranular laminated principle to crush granite, it make the most of the granite to realize the phenomenon of "stone hitting stone" in crushing cavity, to replace the traditional single grain crushing principle, it realize the selective crushing of material, increased the proportion of fine material products and the cube content, largely reduced the needle flake material, while reduce wear of wear parts.

The picture details