Cheap Mining Machine/Crushing Equipment for Sale

Zhengzhou General Mining Machinery Co., Ltd.- Type:Jaw Crusher

- Application:Machinery & Hardware, Art & Craft, Chemical, Construction, Mineral Industry, Stone Industry

- Drive:Electric

- Crushing Style:Extruding

- Compressive Strength (For Crushing):>300MPA

- Crushing Degree:Intermediate Crusher

Base Info

- Model NO.:PE200*350

- Finished Surface:Cut Off Tool

- Certification:CE, ISO, SGS

- Condition:New

- Color:Yellow

- Size of Feeder Opening:200*350mm

- Max. Feeding Size:180mm

- Size of Output:15-50mm

- Capacity:1-6t,H

- Motor Power:11kw

- Overall Dimension:996*800*760

- Weight:1.2t

- Installation:Under The Guidance of Engineer

- After-Sale Service:Training, Technical Support, etc.

- Warrenty:1 Year

- Transport Package:International Packing Standard

- Specification:ISO, CE, SGS Certificate.

- Trademark:TYM

- Origin:China

- HS Code:8474201000

- Production Capacity:60 Sets,Month

Description

Basic Info.

Model NO. PE200*350 Finished Surface Cut Off Tool Certification CE, ISO, SGS Condition New Color Yellow Size of Feeder Opening 200*350mm Max. Feeding Size 180mm Size of Output 15-50mm Capacity 1-6t/H Motor Power 11kw Overall Dimension 996*800*760 Weight 1.2t Installation Under The Guidance of Engineer After-Sale Service Training, Technical Support, etc. Warrenty 1 Year Transport Package International Packing Standard Specification ISO, CE, SGS Certificate. Trademark TYM Origin China HS Code 8474201000 Production Capacity 60 Sets/MonthProduct Description

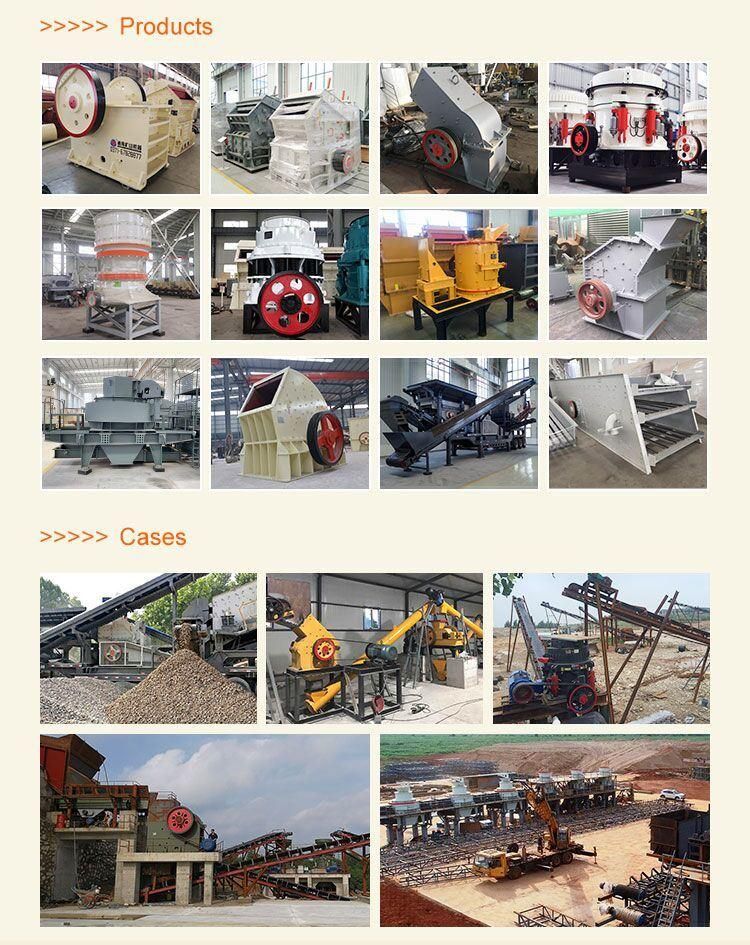

Jaw crusher 1.The application of Jaw Crusher:Jaw crusher widely used for crushing various materials like stone, granite, trap rock, coke, coal, manganese ore, iron ore, emery, fused aluminum, oxide, fused calcium carbide, lime stone, quartzite, alloys, etc.

2.Working Principle of Jaw Crusher:

The motor transmits power through belt, drives the moving jaw do periodic motion to the fixed jaw surround the eccentric shaft. The angle between toggle plate and moving jaw increases when moving jaw moves up. So the moving jaw closes to the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves away from fixed jaw by the pulling of rod and spring, the products such as stone after crushing will be discharged from the outlet.

3.Characteristics of Jaw Crusher:

a. High ratio of crushing

b. Homogeneous final grain size

c. Simple structure

d. Reliable working condition

e. Easy maintenance

f. Low operating cost

4.Technical parameter

| Model | Size of Feeder Opening (mm) | Max. Feeding Size (mm) | Capacity(t/h) | Motor Power (KW) | Overall Dimensions (mm) | Weight (t) |

| PE150× 250 | 150× 250 | 125 | 1-3 | 5.5 | 896× 745× 935 | 0.8 |

| PE250× 400 | 250× 400 | 200 | 5-20 | 15 | 1430× 1310× 1340 | 3 |

| PE400× 600 | 400× 600 | 350 | 15-60 | 30--37 | 1700× 1732× 1653 | 7 |

| PE500× 750 | 500× 750 | 425 | 50-100 | 45--55 | 2035× 1921× 2000 | 12 |

| PE600× 900 | 600× 900 | 480 | 60-130 | 55--75 | 2290× 2206× 2370 | 17 |

| PE750× 1060 | 750× 1060 | 630 | 80-180 | 90--110 | 2655× 2302× 3110 | 29 |

| PE900× 1200 | 900× 1200 | 750 | 140-260 | 110-132 | 3789× 2826× 3025 | 58 |

| PEX250× 750 | 250× 750 | 210 | 10-40 | 22--30 | 1667× 1545× 1020 | 5 |

| PEX250× 1000 | 250× 1000 | 210 | 15-50 | 30--37 | 1550× 1964× 1380 | 7 |

| PEX250× 1200 | 250× 1200 | 210 | 20-60 | 37--45 | 2192× 1900× 1950 | 8.5 |

Packing and shipping

Packing and shippingStandard parts are packed in the wooden boxes, and the big parts are packed with plastic membrane.The whole machine is loaded in the container.We can also pack them according to your requirement.

Related Products