2018 New Design High Quality Small Diesel Engine Jaw Crusher

Shanghai Zenith Mineral Co., Ltd.- Type:Jaw Crusher

- Application:Construction, Mineral Industry, Stone Industry

- Drive:Hydraulic

- Crushing Style:Grinding & Impact

- Compressive Strength (For Crushing):>300MPA

- Crushing Degree:Intermediate Crusher

Base Info

- Model NO.:PEW250x1200, PEW400x600, PEW760, PEW860

- Finished Surface:Hole Process

- Certification:CE, ISO, GOST

- Condition:New

- Color:Iron Grey

- Spare Parts Supply:for Whole Year

- Test&Installation:Engineer Assigned

- After-Sale Service:for Whole Using Life

- Export Markets:Global

- Transport Package:Container, Nude Packs, in Bulk

- Specification:CE, ISO

- Trademark:Zenith

- Origin:Shanghai Zenith, China

- HS Code:8474209000

- Production Capacity:80sets,Month

Description

Basic Info.

Model NO. PEW250x1200, PEW400x600, PEW760, PEW860 Finished Surface Hole Process Certification CE, ISO, GOST Condition New Color Iron Grey Spare Parts Supply for Whole Year Test&Installation Engineer Assigned After-Sale Service for Whole Using Life Export Markets Global Transport Package Container, Nude Packs, in Bulk Specification CE, ISO Trademark Zenith Origin Shanghai Zenith, China HS Code 8474209000 Production Capacity 80sets/MonthProduct Description

2018 New design high quality small diesel engine jaw crusherdiesel engine jaw crusher introduction:

diesel engine jaw crusher are typically used as primary crushers, or the first step in the process of reducing rock. They typically crush using compression. The rock is dropped between two rigid pieces of metal, one of which then move inwards towards the rock, and the rock is crushed because it has a lower breaking point than the opposing metal piece.

diesel engine jaw crusher movement is obtained by using a pivot point located at one end of the "swing jaw", and an eccentric motion located at the opposite end.

diesel engine jaw crusher working principle:

The motor transmits power through belt, drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft. The angle between toggle plate and moving jaw plate increases when moving jaw moves . So the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet.

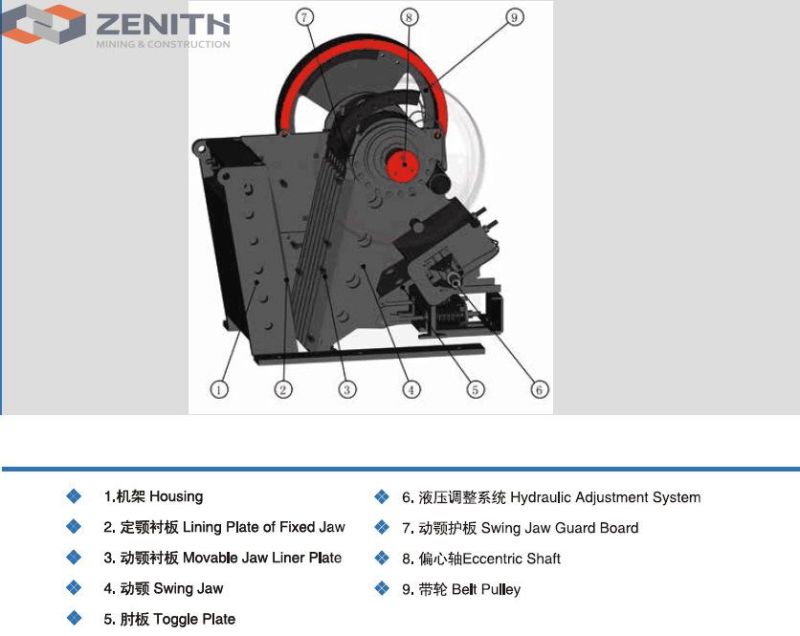

diesel engine jaw crusher composition-structure:

It is made up of frame, eccentric shaft, grooved wheel, flywheel, moving jaw, side guard plate, toggle plate, toggle backseat, adjusting screw, returning spring, fixed jaw plate and moving jaw plate. Toggle plate is of safety function.

diesel engine jaw crusher features:

Big capacity and energy saving: No dead zone, feeding and crushing efficiency is greatly improved.

"V"-shape structure: The actual width of feed is the same as nominal width.

Good performance and good stability.

Lubrication system: Safe, reliable and convenient, easy to maintenance.

Work long time: The internal structural precision greatly extend the life of equipment.

Adjustment device: Increase the flexibility of the equipment.

Low noise and less dust.

Easy operation and maintenance, low operating costs.

Application of diesel engine jaw crusher

1.widely applied in mining, road&railway, concrete, chemical and building material industries.

2.Ores and rocks with various hardness

3.Concrete basis and steel structure basis

4.Stationary, half-mobile and mobile applications

diesel engine jaw crusher technical data:

| Model | Feed Opening (mm) | Max Feeding (mm) | Discharge Opening (mm) | Capacity (t/h) | REV (r/min) | Power (kw) | Motor Model | Machine Size (mm) |

| PEW250×1000 | 250×1000 | 220 | 20-40 | 15-50 | 330 | 6-37 | Y250M-6/37 | 1400×1850×1310 |

| PEW250×1200 | 250×1200 | 220 | 20-40 | 20-50 | 330 | 6-37 | Y250M-6/37 | 1400×2050×1310 |

| PEW400×600 | 400×600 | 350 | 35-85 | 15-70 | 250 | 6-37 | Y250M-6/37 | 1920×1460×1840 |

| PEW760 | 760×1100 | 620 | 75-200 | 150-350 | 270 | 6-110 | Y315L1-6/110 | 2600×2500×2200 |

| PEW860 | 860×1100 | 720 | 100-225 | 200-500 | 240 | 6-132 | Y315L2-6/132 | 3300×2320×3120 |

| PEW1100 | 1100×1200 | 930 | 150-275 | 300-650 | 210 | 8-185 | Y355L1-8/185 | 4140×2660×356 |