High Precision Head 45 Degree Tilt Stone Chauffeuring Machine PLC-700

Fujian Wanlong Diamond Tool Co., Ltd.- Warranty:12 Months

- Type:Laser Cutting Machine

- Usage:Ceramics, Glass, Fire Brick, Red Brick, Jadestone, Cement Brick, Concrete Curb, Granite, Marble

- Application:Machinery & Hardware, Art & Craft, Chemical, Construction, Mineral Industry, Stone Industry

- Source Voltage:380V

- Automation:Automatic

Base Info

- Model NO.:PLC-700 YTQQ-600

- Cutting Ability:High Speed

- Control:CNC

- Certification:API, CCC, UL, SONCAP, GOST, ISO, CE

- Main Motor Power:15,18.5,22kw

- Voltage:220,380,415V

- After Sales Service Provide:Engineer Available Service Machinery Overseas

- Work Table Rotation:0-45,90,360

- Head Tilting Degree:0-90

- Max. Processing Size:3200X2000X230mm

- Transport Package:Seaworthy Wooden Case for Automatic Cutting Machin

- Specification:6000X5500X3360mm

- Trademark:Wanlong

- Origin:China

- HS Code:84641000

- Production Capacity:5000sets Per Year

Description

Basic Info.

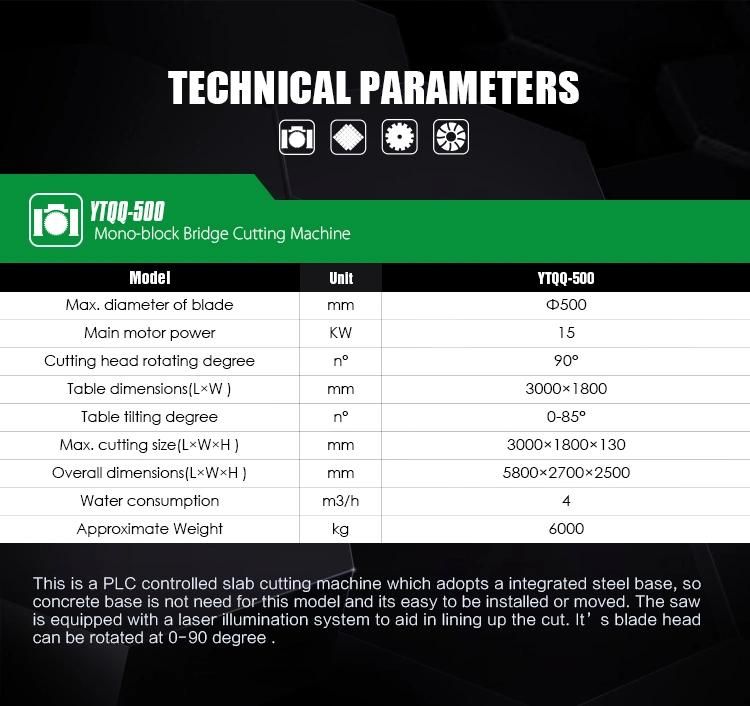

Model NO. PLC-700 YTQQ-600 Cutting Ability High Speed Control CNC Certification API, CCC, UL, SONCAP, GOST, ISO, CE Main Motor Power 15/18.5/22kw Voltage 220/380/415V After Sales Service Provide Engineer Available Service Machinery Overseas Work Table Rotation 0-45/90/360 Head Tilting Degree 0-90 Max. Processing Size 3200X2000X230mm Transport Package Seaworthy Wooden Case for Automatic Cutting Machin Specification 6000X5500X3360mm Trademark Wanlong Origin China HS Code 84641000 Production Capacity 5000sets Per YearProduct Description

High efficiency for cutting slab & tile, stable and reliable

Feature

1. Wide bridge structure with crossbeam, large size of slab cutting available

2. Equipped with infrared device, precise cutting location reachable

3. Dustproof design of the slide track ensures the precise guide movement & long lifespan

4. Worktable can tilt & rotate in wide angle for special processing

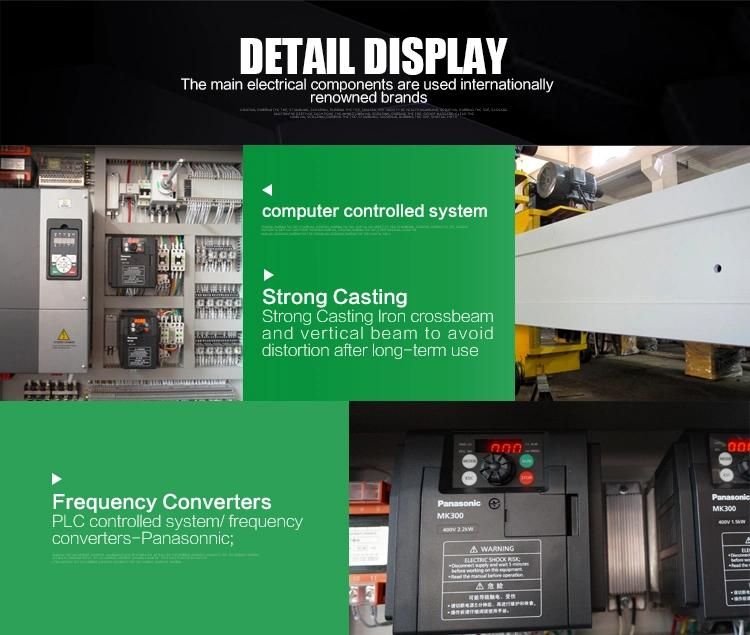

5. PLC control system, programmable, fully automatic & smooth feeding

6. Precise movement of head in X, Y, Z directions by rack & gear

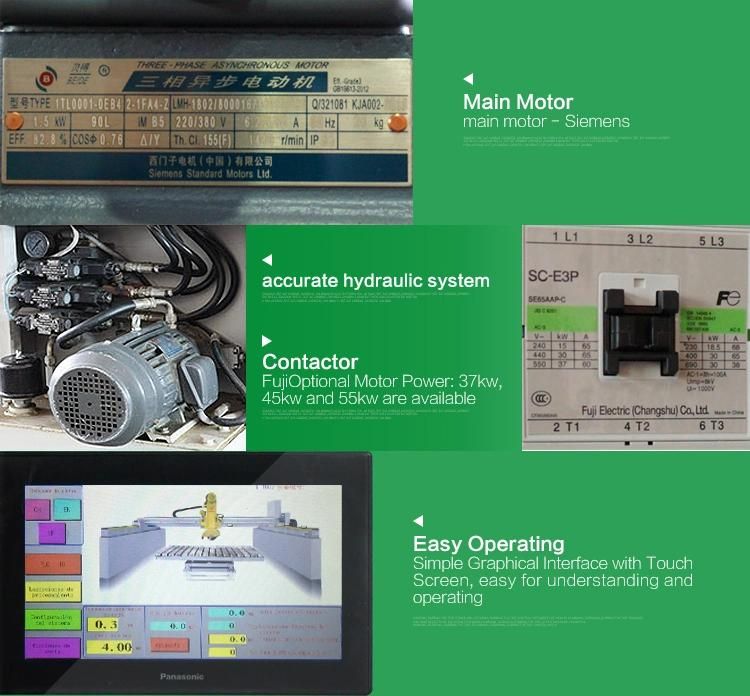

7. Electric parts of Japanese name brand adopted, reliability guaranteed

8. Touch-sensitive operating system, friendly human-machine interface design

9. CE certificate

The crossbeam is made of strong cast iron to avoid distortion after long run

Guide rail is oil impregnated and protected from water and dust

Vertical movement of machine head is driven by hydraulic system, and the stroke is adjustable

Horizontal movement of the crossbeam is driven by motor equipped with OMRON rotary encoder by which the precision is guaranteed

Worktable can tilt 0-85° , and rotate 0-360° .

Equipped with Panasonic frequency transducer and OMRON PLC, programmable and fully automatic

Lead Time: 30 days after receipt the down payment.