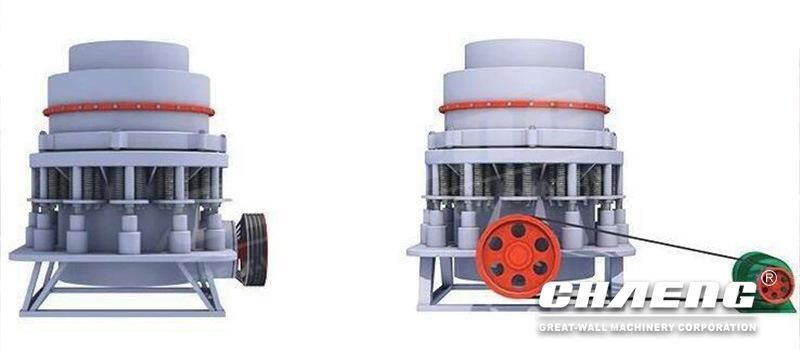

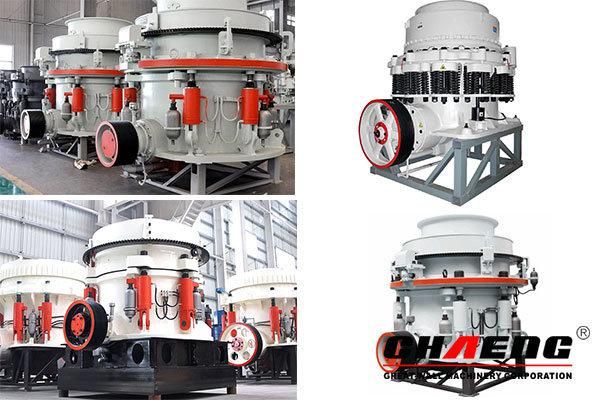

High Performance Cone Crusher for Hard Stone and Iron Ore

Xinxiang Great Wall Machinery Co., Ltd.- Type:Cone Crusher

- Application:Construction, Mineral Industry, Stone Industry

- Drive:Hydraulic

- Crushing Style:Grinding & Impact

- Compressive Strength (For Crushing):>300MPA

- Crushing Degree:Intermediate Crusher

Base Info

- Model NO.:cone crusher

- Finished Surface:Thread Process

- Certification:CE, ISO

- Condition:New

- Color:Customized

- Input Size:0-350mm

- Material:Granite, Diabase, Basalt, Pebble, Limestone, Dolom

- Motor Power(Kw):132-630

- Transport Package:Transport Package

- Specification:45-1200t,h

- Trademark:CHAENG

- Origin:Henan

- Production Capacity:45-1200t,H

Description

Basic Info.

Model NO. cone crusher Finished Surface Thread Process Certification CE, ISO Condition New Color Customized Input Size 0-350mm Material Granite, Diabase, Basalt, Pebble, Limestone, Dolom Motor Power(Kw) 132-630 Transport Package Transport Package Specification 45-1200t/h Trademark CHAENG Origin Henan Production Capacity 45-1200t/HProduct Description

Introduction of Stone Cone Crusher

Cone crusher is also a kind of spring safety type cone crusher, which concentrates on the specialty of high-frequency,optimization of cavity and reasonable impact.it is based on the conceptions of laminated crushing principle and more crushing and less grinding.Our hydraulic cone crusher has muti-cylinder with advanced design which imports the most advanced technology. After many years of practicing, we produce this kind of hydraulic cone crusher at last. Its performance reached the advanced level of the whole industry, and it is the ideal choice for the mining equipment. By using hydraulic motor to adjust the discharging opening size on-load is very easy, which makes the crushing loop balance and realizes high production efficiency. If you want to realize full-automatic control with DCS collecting and distributing control system, it only needs to install hydraulic motor position sensor to track the discharging opening size of the crusher. All the components can be disassembled and miantained from the top or side of the crusher, and moveable cone and fixed cone are disassembled easily without dismounting the main frame and fastening bolt. It is convenient to replace liner.

Features of Cone Crusher In Sand Crushing Plant

1. Higher capacity and less wear costs.2. Wide range of application suitability.

3. Easy to maintain, reduce the downtime and maintenance costs.

4. Stable running performance and easy operation.

5. Stable bevel wheel transmission device

6. Balanced run out rotation ensures capacity.

7. Proper operation, continuously load until the machine shut down scheduled.

Working Principle of cone crusher

When the cone crusher is working, the motor drives the eccentric bearing bushing via spring coupling, transmission shaft and a couple of cone gear wheel. The crushing cone axis is forced to swing by the eccentric bearing bushing, which makes the mantle sometimes close to the bowl liner, and sometimes far away from the bowl liner. The raw materials are pressed, impacted and finally crushed in the crushing chamber.

Specification of cone crusher

| Model | Discharge size | Installed Power | Min. capacity | Max. capacity | Chamber | Auxiliary classification |

|---|---|---|---|---|---|---|

| GCPF500 | 32mm | 400Kw | 400t/h | 530t/h | C2 thick | HP Hydraulic |

| GCPF300 | 16mm | 220Kw | 170t/h | 215t/h | M middle | HP Hydraulic |

| GCPF500 | 38mm | 400kw | 425t/h | 580t/h | C1 Super thick | HP Hydraulic |

| GCPF300 | 22mm | 220Kw | 220t/h | 260t/h | C2 thick | HP Hydraulic |

| GCPF440 | 25-51mm | 220Kw | 195t/h | 486t/h | S1 middle thick | Single Cylinder Hydraulic |

| GCPF440 | 29-51mm | 220Kw | 225t/h | 511t/h | S1 middle thick | Single Cylinder Hydraulic |

| GCPF440 | 35-54mm | 220Kw | 267t/h | 601t/h | S1 Super thick | Single Cylinder Hydraulic |

| GCPF660 | 38mm | 315Kw | 318t/h | 895t/h | S2 middle thick | Single Cylinder Hydraulic |

| GCPF660 | 41mm | 315Kw | 345t/h | 1050t/h | S1 middle thick | Single Cylinder Hydraulic |

Advantages of cone crusher in Sand Crushing Plant

1.Good grain shape, large output;

2.Less consumption of vulnerable parts, low operating cost;

3.Hydraulic protection and hydraulic cavity cleaning with high degree of automation to reduce downtime;

4.Thin oil lubrication to improve service life;

5.It can be installed both in the plant and on the concrete foundation;

6.With multi-cylinder crushing cavity, it can produce intermediate, fine and ultra-fine proudcts by just replacing different cavities.

About CHAENG

1.Based on high-end and advanced equipment

With large casting base, machining and assembling workshop, CHAENG has strong casting and processing strength. All the main engines for the turnkey project are self-made, and other supporting auxiliary machines are bought from excellent brands at home and abroad, which means that we can control the whole quality and construction period of the project.

2.Multiple patents, controlling the core technologies

The company has a professional technical team in many fields with more than 100 people, such as technology, equipment, hydraulic, electrical and civil engineering. So we can design the whole sandstone aggregate production line independently. We stick to independent research and innovation all the time, continuously optimize product performance and improve the technological content of products. We have research center of aggregate, powder and high-performance concrete, so we can provide scientific and professional sandstone aggregate production system solutions for the customers.

CHAENG has won man honorary awards, such as "top 100 suppliers in China cement industry", "top 10 innovative enterprise in China cement industry", "high-growth private enterprise in Henan Province", "technological innovation demonstration enterprise of energy conservation and emission reduction in Henan Province", "National high-tech enterprise" and so on.