High Quality Stone Impact Crusher Rock Impact Crusher Price

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Type:Jaw Crusher

- Application:Machinery & Hardware, Art & Craft, Chemical, Construction, Mineral Industry, Stone Industry

- Drive:Electric

- Crushing Style:Grinding & Impact

- Compressive Strength (For Crushing):>300MPA

- Crushing Degree:Coarse Crusher

Base Info

- Model NO.:PF1315

- Finished Surface:Cut Off Tool

- Certification:CE, ISO

- Power:30-350kw

- Weight:3.5-26.5t

- Delivery Time:15 Days

- After Sale Service:Long Term, Good Price

- Guarantee:12 Months

- Installation:Under Our Guide

- Machine Condition:New

- Working Condition:Durable

- Transport Package:Standard Packing

- Specification:CE

- Trademark:HC

- Origin:Gongyi City, Henan Province, China

- HS Code:8474201000

- Production Capacity:50 Sets, Month

Description

Basic Info.

Model NO. PF1315 Finished Surface Cut Off Tool Certification CE, ISO Power 30-350kw Weight 3.5-26.5t Delivery Time 15 Days After Sale Service Long Term, Good Price Guarantee 12 Months Installation Under Our Guide Machine Condition New Working Condition Durable Transport Package Standard Packing Specification CE Trademark HC Origin Gongyi City, Henan Province, China HS Code 8474201000 Production Capacity 50 Sets/ MonthProduct Description

High Quality Stone impact crusher rock impact crusher priceIntroduction

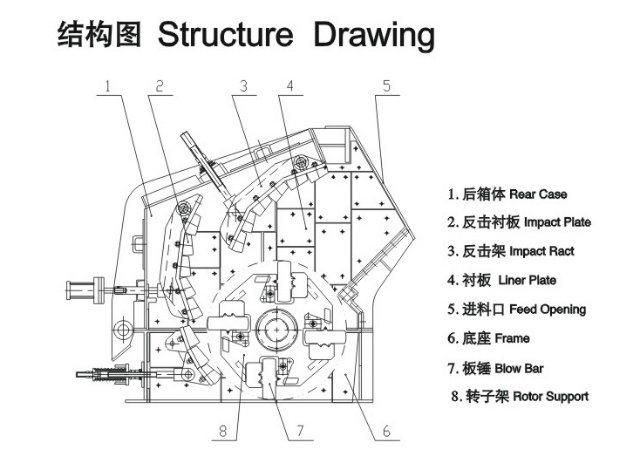

Mining Impact Crusher is widely used to crush the medium hardness brittle materials such as limestone, dolomite, shale, sandstone, coal, asbestos, graphite, and rock salt etc. In building materials, chemicals, coal and other industries. It has the advantages of large crushing ratio, usually 10-20, and maximum 50-60; Simplified crushing process, unique structure, easy manufacture, and convenient operating and maintenance.

Features:

1. Simple structure

2. Easy maintenance

3 stable performance

4. Even particles

5. High crushing ratio

Impact crusher's work principle

Impact breaker impact crushers crush materials with impact force.

Compare to other crushers, our impact crusher has bigger reduction ratio and can fully use the high speed impactenergy of entire rotor. But because the impact crusher board hammer isextremely easy to wear, it also is restricted in the hard material staveapplication. Impact crusher is usually used to break thick garrulous, garrulousor the limestone, the coal, the calcium carbide, the quartz, the dolomite, thecuring iron ore, the gypsum and the industrial chemicals which are hardfollowing brittle material.

The ideal entering material granularity of our PF type impact crusher is 100-500mm, themost greatly is not surpass the rating. The materail granularity user canajusts the hammer head and the impact board and th gap between component, according to theirs demands

Technical Data

Model | Rotor Size (mm) | Max.Input Size (mm) | Output size (mm) | Motor power (kw) | Capacity (t/h) | Weight (kg) |

PF-0807 | 850 × 700 | 300 | ≤ 25=85% | 30 | 10-25 | 3500 |

PF-1007 | 1000 × 700 | 300 | ≤ 25=85% | 37 | 15-30 | 6500 |

PF-1010 | 1000 × 1050 | 350 | ≤ 25=85% | 55-75 | 50-80 | 12100 |

PF-1210 | 1250 × 1050 | 350 | ≤ 25=85% | 110-132 | 70-120 | 14000 |

PF-1214 | 1250 × 1400 | 400 | ≤ 25=85% | 132-160 | 130-180 | 18500 |

PF-1315 | 1300 × 1500 | 500 | ≤ 25=85% | 160-200 | 180-260 | 23500 |

PF- 1320 | 1320× 2000 | 500 | ≤ 25=85% | 300-350 | 300-350 | 26500 |