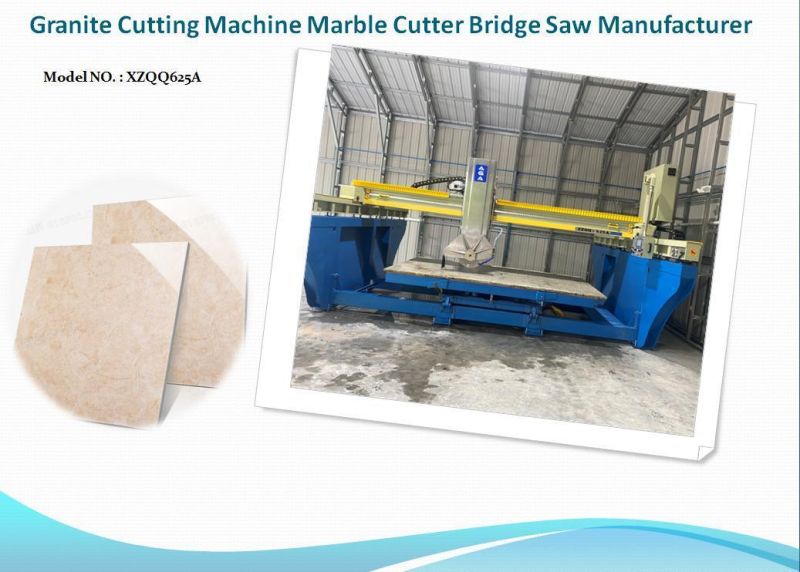

5 Axis Bridge Saw Cutting Machine CNC New Title Table Edge Polishing Stone Cutting Saw Machine for Granite Marble Quartz Cutter

Xiamen Aga Import and Export Co., Ltd.- After-sales Service:1 Year

- Warranty:1 Year

- Type:Laser Cutting Machine

- Usage:Granite, Marble

- Application:Machinery & Hardware, Stone Industry

- Source Voltage:380V

Base Info

- Model NO.:XZQQ625A

- Automation:Automatic

- Cutting Ability:High Speed

- Control:CNC

- Certification:ISO, CE

- Max. Cut Size (Lxw):3200X2000 mm

- Max. Cut Thick:170mm

- Table Tilting:0-85°

- Table Rotation:0-360°

- Blade Tilting:0-45°

- Max. Blade Size:625mm

- Spindle Motor:15 Kw

- Weight:7200kg

- Transport Package:Plastic Packing

- Specification:Dimention: 6x5x3 m

- Trademark:AGA

- Origin:Xiamen, Fujian, China

- HS Code:84641010

- Production Capacity:100sets,Month

Description

Basic Info.

Model NO. XZQQ625A Automation Automatic Cutting Ability High Speed Control CNC Certification ISO, CE Max. Cut Size (Lxw) 3200X2000 mm Max. Cut Thick 170mm Table Tilting 0-85° Table Rotation 0-360° Blade Tilting 0-45° Max. Blade Size 625mm Spindle Motor 15 Kw Weight 7200kg Transport Package Plastic Packing Specification Dimention: 6x5x3 m Trademark AGA Origin Xiamen, Fujian, China HS Code 84641010 Production Capacity 100sets/MonthProduct Description

Product Description

5 Axis Bridge Saw Cutting Machine CNC New Title Table Edge Polishing Stone Cutting Saw Machine for Granite Marble Quartz Cutter

XZQQ625A is our newly designed CNC bridge saw with compact size.

1. It is with automatic 360 degree tilting main head and hydraulic tilting work table.

2. By using advanced computer control system to achieve multi programming methods, including manual programming or PC programming ,

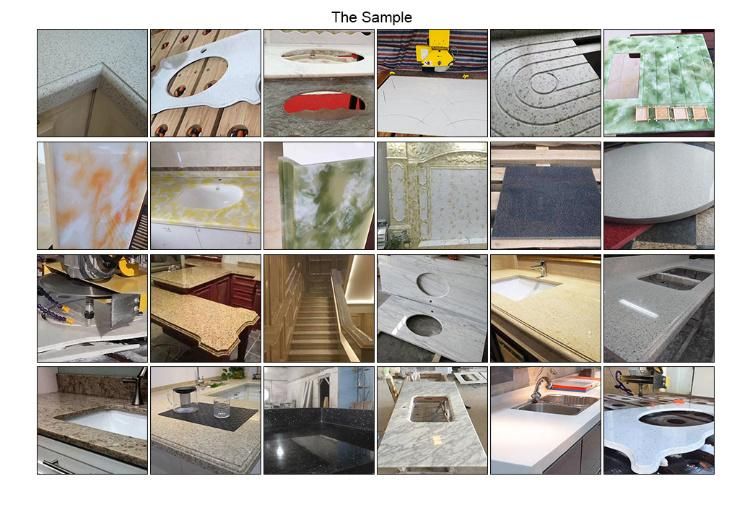

3. Achieve fully automatic processing operation and some powerful functions, like easy-operation auto cutting, edge polishing, slotting, kitchen countertop processing, special shape processing and other operations.

Technical Parameters

| Blade size | 400-625mm 16"-25" |

| Cut length | 3200mm 126" |

| Cut width | 2000mm 78" |

| Cut thick | 170mm 7" |

| Blade tilt | 0 - 45° |

| Table rotate | 0 - 360° |

| Table tilt | 0 - 85° |

| Spindle motor | 15kw 20HP |

| Size (L×W×H) | 6×5×3 m |

| Weight | 7200kg 16000lbs |

- Compact structure, small area coverage, no need to do ground foundation.

- Using advanced computer control system to achieve higher working efficiency.

- Powerful functions combined in one machine to achieve almost all processing works for small sized factory.

- High quality electrical components with long service life and low maintenance cost.

Main 3 functions: cutting, edge polishing and sink hole cutting.

Packing details:

About us:

AGA has been devoting to making machinery for processing and fabrication of marble granite and providing reliable. The products include bridge saw, block cutter, polishing machine as well as equipments for other construction stones. The equipments have been successfully exported to world stone market in USA, Canada, Europe, MID east, Egypt, India, etc.

AGA understands that machinery creates value for customer and every machine comes from sophisticated technology and is manufactured by dedicated and experienced workers under strict inspection and full test. AGA insists on equipments of high quality and advanced technology to assist customers in their pursuit of a true competitive advantage. Our philosophy is all about professional entrepreneurship and perfectly serving our clients and the mission is to help customers because by choosing us you are giving us a chance to make your machine more productive that also make your products unrivaled in the competitive market and we are happy to do that professionally and passionately.

For more details information, please visit our website: agastonemachine.en.made-in-china.com or agastonemachine.en.made-in-china.com , thanks !

FAQ.

Q1: This is the first time I buy the machine, is it easy to operate?

We can provide the operation manual or video for guiding. If it is hard for you learning, we can also help you by "Team viewer"online, with telephone or Skype explain.

Q2: How to choose a suitable machine?

You can tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience.

Q3: How can I trust your company and your products?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure they can work very well before being out of factory. The testing video and pictures will be available before delivery.

Q4: If machine have any problem after I ordered it, what could I do?

Free parts send to you in machine warranty period if machine have any problem. Free after-sales service life for machine, please feel free contact us if your machine have any problem. We will give you 24hours service from phone and whatsapp.

Q5: Can I visit your factory?

Yes! We greatly welcome customers to visit our factory!

Q6: What's your date of delivery?

For standard machine, about 15 working days; For customized machine, about 20 working day.

Q7: MOQ?

Our MOQ is 1 set machine. We could send machine to your country port directly, please tell us your port name. There will be best shipping freight and machine price send to you.