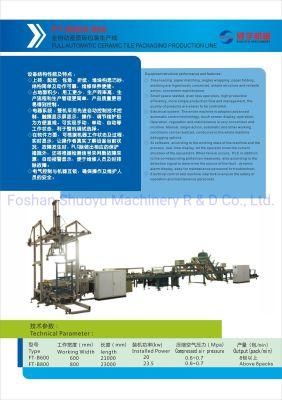

Full Automatic Tiles Packaging Line

Foshan Shuoyu Machinery R & D Co., Ltd.- Type:Ceramic Tiles Polishing Line

- Control:CNC

- Automation:Automatic

- Precision:High Precision

- Application:Ceramics

- Type for Grinding Machine:Disc Grinding Machine

Base Info

- Model NO.:FT-B600 -800

- Grinding Machine Type:Main Beam Swing Machine

- Grinding Method:Wet Grind

- Certification:ISO

- Condition:New

- Ceramic Tiles:Smart Tiles Packaging Line

- Quality:European Standard

- Delivery Schedule:20days on Time Delivery

- Capacity:Customized

- ODM:Available

- OEM:Available

- Transport Package:International Export Standard

- Specification:600mm,800mm

- Trademark:Shuoyu

- Origin:China

- Production Capacity:100sets Per Year

Description

Basic Info.

Model NO. FT-B600 -800 Grinding Machine Type Main Beam Swing Machine Grinding Method Wet Grind Certification ISO Condition New Ceramic Tiles Smart Tiles Packaging Line Quality European Standard Delivery Schedule 20days on Time Delivery Capacity Customized ODM Available OEM Available Transport Package International Export Standard Specification 600mm/800mm Trademark Shuoyu Origin China Production Capacity 100sets Per YearProduct Description

Full automatic ceramic tile packaging production line is Shuoyu machinery new developed ceramic tile packaging machine, mainly applied for packing different sizes of polished tiles and rustic tiles etc. with low energy consumption, high efficiency, large output, simple operation and high degree of automation etc. characteristics.Equipment structure performance and features:

Tiles loading, paper matching, angles wrapping, paper folding, stacking are ingeniously conceived, simple structure and reliable action, convenient maintenance.

Small space needed, even less operators, high production efficiency, more simply production flow and management, the quality of products are easier to be controlled.

Electrical system: The entire machine is adopted advanced automatic control technology, touch screen display, operation, Operation, regulation and maintenance is very convenient and intuitive. Manual, single action, automatic and other working conditions can be realized, conducive to the whole machine debugging options.

At software, according to the working state of the machine and the process, real-time display, let the operator know the current situation of the equipment. When failure occurs, PLC in addition to the corresponding protection measures, also according to the detection signal to determine the source of the fault , dynamic alarm display, easy for maintenance personnel to troubleshoot.

Electrical control and machine interlock to ensure the safety of operation and maintenance personnel.

Our services:

A.Pre-sales service:1.Indicate the specified function and equipment configuration.

2Professional feedback on all kinds of technical questions.

3.Help to meet the needs of the individualized product.For example,OEM,ODM.4.Welcome to visit our factory at any time.

B.On-purchase service:

1.Provide the product performance and technical specification doc sheets.

2.Confirm the changes or special requirements in the production process.

3.Welcome to visit our factory for inspection.

C.After-sales service:

1.Provide installation,commisioning,operation,maintenance and other guidance.

2.Provide easy-wearing parts and common used spare parts.

3.24 hours on line service.

4.Engineers available to service machinery overseas

5.One year warranty, provide lifetime free technical upgrade support and maintenance services.