50-150tph Stone Rock Crushing Plant Equipment

Shanghai Zenith Mineral Co., Ltd.- Application:Construction, Mineral Industry, Stone Industry

- Drive:Electric

Base Info

- Model NO.:YF series

- Crushing Style:Grinding & Impact

- Compressive Strength (For Crushing):>300MPA

- Crushing Degree:Intermediate Crusher

- Finished Surface:Hole Process

- Certification:CE, ISO, GOST

- Condition:New

- Color:Iron Grey

- Spare Parts Supply:for Whole Year

- Test&Installation:Engineer Assigned

- After-Sale Service:for Whole Using Life

- Export Markets:Global

- Transport Package:Container, Nude Packs, in Bulk

- Specification:ISO9001: 2000

- Trademark:Zenith

- Origin:China

- HS Code:8474209000

- Production Capacity:80sets,Month

Description

Basic Info.

Model NO. YF series Crushing Style Grinding & Impact Compressive Strength (For Crushing) >300MPA Crushing Degree Intermediate Crusher Finished Surface Hole Process Certification CE, ISO, GOST Condition New Color Iron Grey Spare Parts Supply for Whole Year Test&Installation Engineer Assigned After-Sale Service for Whole Using Life Export Markets Global Transport Package Container, Nude Packs, in Bulk Specification ISO9001: 2000 Trademark Zenith Origin China HS Code 8474209000 Production Capacity 80sets/MonthProduct Description

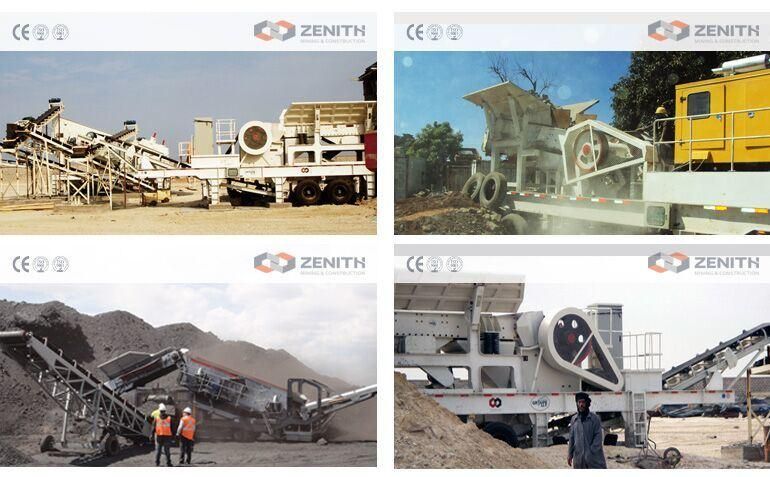

50-150tph stone rock crushing plant equipmentcrushing plant equipment introduction:

crushing plant equipment provides a new field of business opportunities for contractors, quarry operators, recycling and mining applications. crushing plant equipment concept is fully adaptable to all mobile crushing needs, it set up a new range of business opportunities for coarse and fine crushing. It can eliminate the obstacles of the crushing places and circumstances, and offer the high efficient and low cost project plants for the client. To the client, it is the best choice.

crushing plant equipment features:

1. Incorporated the feeder, belt conveyor and vibrating screen into the crusher

2. Steering traction axis, convenient for road transportation

3. Support legs on truck, quick to set-up

4. Electric motor and control cabinet are incorporated

crushing plant equipment structure:

1. Vibrating feeder

2. Motor of feeder

3. Hopper of feeder

4. Jaw crusher

5. Motor of jaw crusher

6. Standard belt conveyor

7. Extended belt conveyor

crushing plant equipment Application

crushing plant equipment is applied to multistage crush large materials, and then screen the discharges according to their different specifications. The whole set plants is widely used to mine, building material, highway, rail way and hydropower industries, etc., finish crushing and screening operations at one time, produce required size and output for consumers.

crushing plant equipment parameters:

| Parameter model | Transport length (mm) | Transport height (mm) | Transport width (mm) | Max. height (mm) | Max. width (mm) | Belt conveyor height (mm) | Total weight (ton) |

| YF938J69 | 11200 | 3900 | 2450 | 4700 | 2900 | 2600 | 42 |

| YF1142J710 | 13000 | 4400 | 2450 | 5100 | 3100 | 2600 | 55 |

| YF1349J912 | 15000 | 4800 | 3000 | 5600 | 3300 | 2800 | 72 |

| Parameter model | Feeder spec | Jaw crusher | Belt conveyor | Extended belt conveyor | Generator | Capacity (t/h) | Power (kw) |

| YF938J69 | GZD-960X3800 | PE600X900 | B650X7M | Optional | Optional | 70-150 | 91.5 |

| YF1142J710 | GZD1100X4200 | PE750X1060 | B800X9M | Optional | Optional | 90-200 | 134 |

| YF1349J912 | GZD-1300X4900 | PE900X1200 | B1000X11M | Optional | Optional | 150-300 | 146 |