50-500tph Jaw Crusher, Stone Crusher Machinery

Shanghai Zenith Mineral Co., Ltd.- Type:Jaw Crusher

- Application:Construction, Mineral Industry, Stone Industry

- Drive:Electric

- Crushing Style:Grinding & Impact

- Compressive Strength (For Crushing):>300MPA

- Crushing Degree:Coarse Crusher

Base Info

- Model NO.:PEW760,PEW860,PEW1100

- Finished Surface:Hole Process

- Certification:CE, ISO, GOST

- Condition:New

- Color:Iron Grey

- Spare Parts Supply:for Whole Year

- Test&Installation:Engineer Assigned

- After-Sale Service:for Whole Using Life

- Export Markets:Global

- Transport Package:Container, Nude Packs, in Bulk

- Specification:ISO9001: 2000

- Trademark:Zenith

- Origin:China

- HS Code:8474209000

- Production Capacity:40-850tph

Description

Basic Info.

Model NO. PEW760/PEW860/PEW1100 Finished Surface Hole Process Certification CE, ISO, GOST Condition New Color Iron Grey Spare Parts Supply for Whole Year Test&Installation Engineer Assigned After-Sale Service for Whole Using Life Export Markets Global Transport Package Container, Nude Packs, in Bulk Specification ISO9001: 2000 Trademark Zenith Origin China HS Code 8474209000 Production Capacity 40-850tphProduct Description

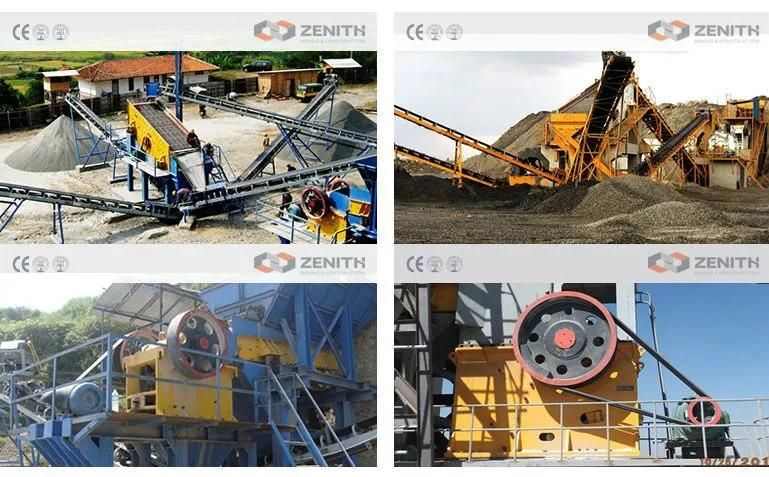

50-500tph Jaw Crusher, Stone Crusher Machinery Brief introduction of stone crusher machineryThe stone crusher machinery is widely used crushing equipment. It has two types, single-toggle type and double-toggle type. Generally, the single-toggle stone crusher machineryis applicable for coarse/medium crushing ores and rocks with compression strength under 250Mpa. The three models of jaw crushers can also crush ores and rocks of different hardness. The PEW single-toggle jaw crusher used for fine crushing is applicable for ores and rocks with medium hardness and below, and the double-toggle jaw crusher can be used to crush ores and rocks with various hardness and high corrosion.

stone crusher machinery Fetures and Advantages The jaw crusher has advantages of simple structure, reliable working, easy operation, convenient maintenance and low cost for equipment and production. stone crusher machinery is widely used in metallurgy, mining, building materials, chemical industry and cement for coarse and medium crushing operations.

stone crusher machinery Working principle The stone crusher machinery is mainly composed of frame body, movable jaw part, toggle plates, locking devices with pull-rod spring and driving devices. The movable jaw is driven by motors for complex pendulum through triangle belt. Once the ores are poured into the crushing cavity crush, they will be extruded, split and bended due to the action of the swing jaw. The crushed ores will be discharged out at the moment when the swing jaw leaves the fixed jaw plate.

stone crusher machinery technical data:

| Model | Feed Inlet Size (mm) | Max Feed Size (mm) | Outlet Range (mm) | Capacity (t/h) | Motor Power (KW) | Weight (ton) | Overall Dimension(mm) |

| PEW760 | 760x1100 | 620 | 75-200 | 150-350 | 110-132 | 24 | 2600× 2500× 2200 |

| PEW860 | 860x1100 | 720 | 100-225 | 200-500 | 132-160 | 32 | 3300× 2320× 3120 |

| PEW1100 | 1100x1200 | 930 | 150-275 | 300-650 | 185-200 | 59.2 | 4140× 2660× 3560 |

| PEW400x600 | 400x600 | 350 | 35-85 | 15-70 | 37 | 6.8 | 1920× 1460× 1840 |

| PEW250x1200 | 250x1200 | 220 | 20-40 | 20-50 | 37 | 6 | 1400× 2050× 1310 |

| PEW250x1000 | 250x1000 | 220 | 20-40 | 15-50 | 30 | 5.6 | 1400× 1850× 1310 |