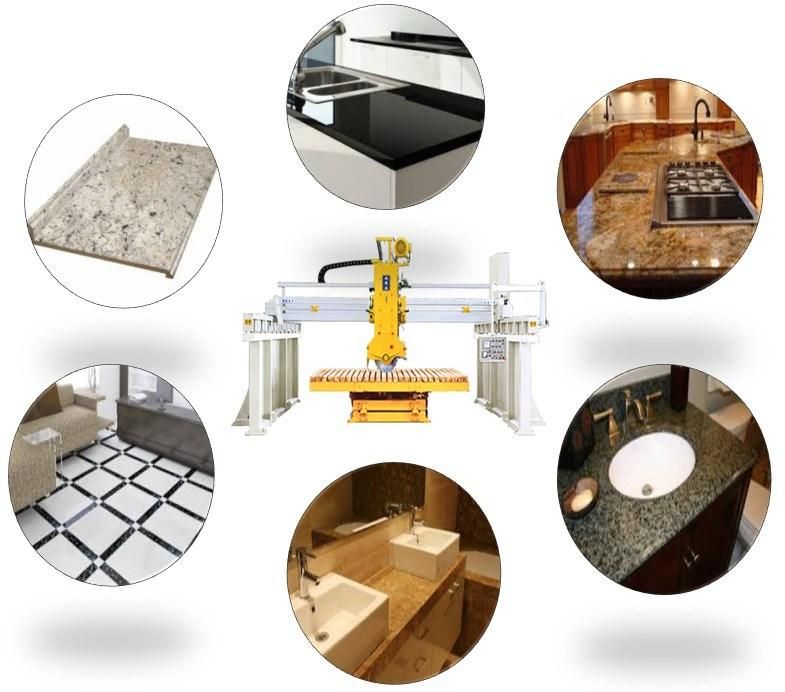

Infrared Slab Cut to Size Machine Granite Marble Cutting Machine (HQ400)

Xiamen Aga Import and Export Co., Ltd.- After-sales Service:24 Hours on Line Services

- Warranty:1 Year Warranty

- Type:Laser Cutting Machine

- Usage:Granite, Marble

- Application:Machinery & Hardware, Construction, Stone Industry

- Source Voltage:220V

Base Info

- Model NO.:HQ400

- Automation:Automatic

- Cutting Ability:High Speed

- Control:CNC

- Certification:ISO, CE

- Size (L*W*H) Hq400:6*5*2.8

- Size (L*W*H) Hq600:6*5*3

- Packaging:Plastic

- Transport Package:Plastic

- Specification:Weight: HQ400 6300k

- Trademark:AGA

- Origin:China

- HS Code:84641010

- Production Capacity:200sets,Month

Description

Basic Info.

Model NO. HQ400 Automation Automatic Cutting Ability High Speed Control CNC Certification ISO, CE Size (L*W*H) Hq400 6*5*2.8 Size (L*W*H) Hq600 6*5*3 Packaging Plastic Transport Package Plastic Specification Weight: HQ400 6300k Trademark AGA Origin China HS Code 84641010 Production Capacity 200sets/MonthProduct Description

Infrared Slab Cut to Szie Machine Granite Marble Cutting MachineProduct No.HQ400

Infrared automatic cutting machine appliable for cutting granite, marble, quartz, sandstone, limestone, etc.

Infrared automatic cutting machine appliable for cutting granite, marble, quartz, sandstone, limestone, etc.Microcomputer control and works automatically by program to cut slab, tiles and kitchen tops efficiently.

Slab cut to size machine granite marble cutting machine specification:

| Model | HQ600 | HQ400 |

| Blade tilting 45° (Angle Cut Mitered) | N/A | N/A |

| Table Rotation 90° | Yes | Yes |

| Table Rotation 0-360° (stopping at each 45°) | Optional | Optional |

| Table tilting 0 - 85° | Yes | Yes |

| Power Of Spindle Motor | 18.5kw / 25 HP | 15kw / 20 HP |

| Max Length of Cutting: (Table Size) | 3200 x 2000mm / 126"x78" | 3200 x 2000mm / 126"x78" |

| Max Thick of Cutting: | 180 mm 7" | 110 mm 4" |

| Steel Walls Included | Optional | Optional |

Slab cut to size machine granite marble cutting machine features:

1. Robust machine comes with strong steel frame, it's optional. If you don't need the steel stand, you can build the concrete stands.

2. Machine microcomputer control and works automatically by program.

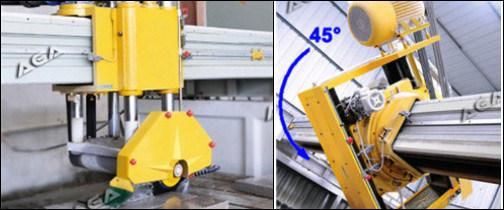

3. The blade goes left and right, up and down, the bridge beam moves forward and backward.

4. Equipped with the infrared device, precise cutting location reachable.

5. Dustproof design of the slide track ensures the precise guide movement & long lifespan

6. The worktable can tilt & rotate in wide-angle for special processing

7. Table tilts up to 85 degree to load the big slabs easily and it also rotates 90 / 360 degree to change the cutting position.

8. Touch screen operation is simple and Laser guide shows the cutting position that makes the cutting easier.

9. Machine head tilting 45 degree for miter cutting is optional.

10. PLC control system, programmable, fully automatic & smooth feeding.

11. Precise movement of head in X, Y, Z directions by rack & gear.

12. Electric parts of international brand adopted, a reliability guaranteed.

13. The touch-sensitive operating system, friendly human-machine interface design.

14. The crossbeam is made of strong cast iron to avoid distortion in the long term use.

15. The guide rail is oil-impregnated and protected from water and dust.

Stone cutting machine, granite cutting machine, marble bridge cutter, bridge cutting machine, marble cutting machine, stone bridge saw, bridge saw, granite bridge saw, stone sawing machine, slab cutting machine, tiles cutting machine, tile cutter, marble grainding machine, slab cutter, cnc machine, cnc cutting machine, etc.

FAQ:

1) Payment:

T/T in advance, 30% deposit, 70% before shipment.

2) Delivery time:

The bridge saw can be shipped immediately when machine in stock; 4-5 weeks ready for shipment when machine not in stock.

Time for ocean shipping depends on where you are located.

3) Shipment:

For FOB or CIF price, we will arrange shipment for you.

4) Documents after shipment:

After shipment, we will send all original documents to you by DHL or Tele-Release, including Packing List, Commercial Invoice, B/L, and other certificates as required by clients.