Jaw Crusher for Iron Ore, Iron Ore Jaw Crusher Machine

Shanghai Zenith Mineral Co., Ltd.- Type:Jaw Crusher

- Application:Construction, Mineral Industry, Stone Industry

- Drive:Electric

- Crushing Style:Grinding & Impact

- Compressive Strength (For Crushing):>300MPA

- Crushing Degree:Intermediate Crusher

Base Info

- Model NO.:PE500x750, PE600x900

- Finished Surface:Hole Process

- Certification:CE, ISO

- Condition:New

- Color:Iron Grey

- Spare Parts Supply:for Whole Year

- After-Sale Service:for Whole Using Year

- Test&Installation:Engineer Assigned

- Export Markets:Global

- Transport Package:Container, Nude Packs, in Bulk

- Specification:ISO9001: 2000

- Trademark:Zenith

- Origin:China

- HS Code:8474209000

- Production Capacity:40-850tph

Description

Basic Info.

Model NO. PE500x750, PE600x900 Finished Surface Hole Process Certification CE, ISO Condition New Color Iron Grey Spare Parts Supply for Whole Year After-Sale Service for Whole Using Year Test&Installation Engineer Assigned Export Markets Global Transport Package Container, Nude Packs, in Bulk Specification ISO9001: 2000 Trademark Zenith Origin China HS Code 8474209000 Production Capacity 40-850tphProduct Description

Jaw Crusher for Iron Ore, Iron Ore Jaw Crusher MachineIron Ore Jaw Crusher Machine is easy to install, debug and maintenance, the continuous improvement and refinement has made it the preferred jaw crusher among professionals and customers. Every feature of Zenith jaw crusher has been carefully designed to provide superior quality and performance. It is widely used in fields of mining, metallurgical, construction, smelting, hydraulic and chemical industries, etc.

Iron Ore Jaw Crusher Machine Application:

Iron Ore Jaw Crusher Machine is often used for coarse and medium crushing operations. It is a high-end product among jaw crushers. It is your choice to efficiently crush hard and strong corrosive materials. Iron ore jaw crusher has become one of the most popular crushers in fields of highway, railways, airport runways, mining, building materials, silicates, metallurgy, chemical industrial raw materials, etc.

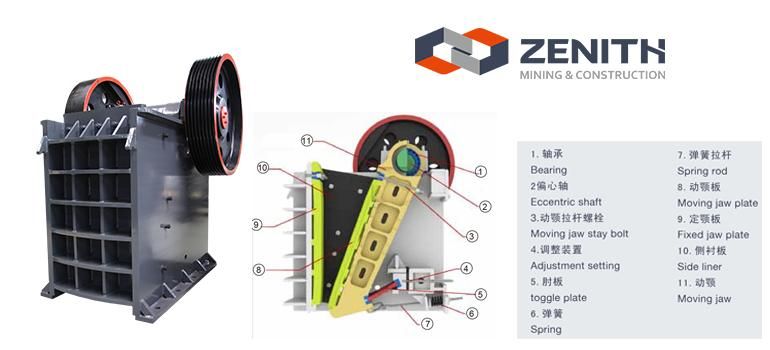

Iron Ore Jaw Crusher Machine Work principle:

The motor drives belt and pulley wheel, making the movable jaw upside and down through the eccentric shaft. When the movable jaw pushes the movable jaw plate close to the fixed jaw plate, materials are crushed or chipped. When movable jaw and its plate get back under the action of eccentric shaft and spring, materials have been crushed are dropped out of the discharge opening. With the continuous rotation of the motor, the movable jaw cyclically crush and discharge materials, realizing mass production.

Iron Ore Jaw Crusher Machine specifications:

| Model | Feeder Opening (mm) | Setting Adjustment Range (mm) | Max. Feeding Size (mm) | Capacity (t/h) | Motor Power (KW) | Weight (t) | Overall Dimension (mm) |

| PE500x750 | 500x750 | 50-100 | 425 | 40-110 | 45-55 | 12 | 2035x1921x2000 |

| PE600x900 | 600x900 | 65-160 | 480 | 90-180 | 55-75 | 17 | 2290x2206x2370 |

| PE750x1060 | 750x1060 | 80-140 | 630 | 110-320 | 90-110 | 29 | 2655× 2302× 3110 |

| PE900x1200 | 900x1200 | 95-165 | 750 | 220-450 | 110-132 | 52 | 3200× 3050× 2950 |

| PE1000x1200 | 1000x1200 | 195-265 | 850 | 315-550 | 110-132 | 57 | 3800× 3166× 3045 |

| PE1200x1500 | 1200x1500 | 150-300 | 950 | 400-850 | 220 | 82.5 | 4200× 3750× 3820 |