Crusher

Chemact (Liaoning) Petrochemicals Ltd.- Type:Impact Crusher

- Application:Machinery & Hardware, Art & Craft, Construction, Mineral Industry, Stone Industry

- Drive:Electric

- Crushing Style:Extruding & Milling

- Compressive Strength (For Crushing):<300MPa

- Crushing Degree:Fine Grinding Machine

Base Info

- Model NO.:CGF1313

- Finished Surface:Thread Process

- Certification:CE, ISO, GOST, SONCAP, UL, CCC, API, ISO, Ce

- Condition:New

- Color:Iron Grey

- Power(W):132-200

- Capacity(T/H):130-200

- Place of Origin:Shanghai, China (Mainland)

- Brand Name:Chuangshen

- Weight:19800

- Quality:China Standard

- Impact Crusher Are Suitable for:Any Demanding Crushing Application

- Price of Impact Crusher:Too Lower

- Certificate:CE, ISO

- Transport Package:Standard Container

- Specification:Industrial grade

- Trademark:chuangshen

- Origin:Shanghai China

- Production Capacity:5set,Day

Description

Basic Info.

Model NO. CGF1313 Finished Surface Thread Process Certification CE, ISO, GOST, SONCAP, UL, CCC, API, ISO, Ce Condition New Color Iron Grey Power(W) 132-200 Capacity(T/H) 130-200 Place of Origin Shanghai, China (Mainland) Brand Name Chuangshen Weight 19800 Quality China Standard Impact Crusher Are Suitable for Any Demanding Crushing Application Price of Impact Crusher Too Lower Certificate CE, ISO Transport Package Standard Container Specification Industrial grade Trademark chuangshen Origin Shanghai China Production Capacity 5set/DayProduct Description

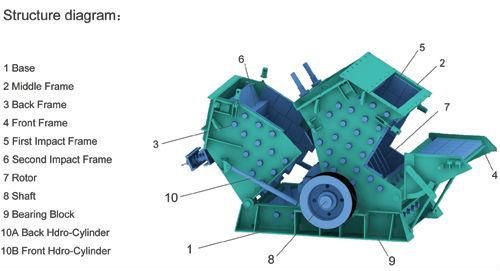

I. CGF Series Impact crushers, stone pulverizing machineI. CGF impact crusher

II. CGF impact crusher, stone pulverizing machine working principle

CGF impact crusher are made of main frame, rotor, front blow bar and back blow bar. Each gyrating cycle is formed by V-belt driving rotor through electronic and materials are crushed by high speed impact of flat hammer on gyrating rotor. After that, the materials are crushed again by throwing impact liner and then crushed again from impact plate to flat hammer. This process works again and again until materials are crushed to qualified size. Materials will keep going back and forth between the first and second crusher chamber untill the crushed ore size is less than the gap between flat hammer and blow bar. then, they will discharge through the setting below the machine as final the product.

III. CGF series impact crusher, stone pulverizing machine design principle

CGF impact crusher have unique design, no key links, outstanding reliability and focus on safety and low energy consumption. Perfectly design combination of heavy rotor, wear resistant and chamber will not only increase yield and quality but also decrease cost and wear resistant parts consumption. The unique fixed equipment of flat hammer makes more reliability of flat hammer. There is a spring release system in the impact equipment can guarantees safety as an overload protection system(Ex:when an iron ore enter into the chamber accidentally). Larger chamber, bigger feed size and increased rotational inertia of rotor means higher reduction ratio, more output and cubic size products. Flat hammer fixing on the rotor through a set of wedges makes bigger torque tightening. There are many clamp spots between flat hammer and rotor which can eliminate the gap between rotor and flat hammer and decrease the damage rate of flat hammer. Using high quality wear resistant parts such as high chromium cast iron increases the service life of wear parts (such as flat hammer, impact liner, sided liner). Using hydraulic controls to open front and back main frame and adjust setting can simplifiy the exchange of flat hammer and adjustment of discharge size. Safety doors on the two sides of the main frame are used for check, maintenance and exchange of wear parts.

| Model | Rotor Diameter (mm) | Rotor Length (mm) | Max Feeding Size (mm) | Capacity (t/h) | Eccentric Shaft Revolutions (r/m) | Power (kw) | Weight (Excluding Motor)(kg) | Over Dimensions (LxWxH)(mm) |

| CGF1008 | 1000 | 800 | 200 | 55~85 | 500~750 | 55~75 | 10184 | 2858x2508x2470 |

| CGF1313 | 1280 | 1340 | 200 | 130~200 | 500~700 | 132~200 | 19800 | 3210x2730x2545 |

| CGF1515 | 1540 | 1500 | 300 | 250~350 | 470~560 | 280~315 | 30000 | 3200x3082x3036 |