Clay Powder Grinding and Modification Process

Shandong ALPA Powder Technology Co., Ltd.- Coating Agent:Staric Acid

- Fineness:5~45um

- Capacity:100~100000kg,H

- Application:Filler. Coatings

- Transport Package:Sea Package

- Specification:flexible arrangement

Base Info

- Model NO.:RTM

- Trademark:ALPA

- Origin:Shandong

- HS Code:8474209000

- Production Capacity:100sets

Description

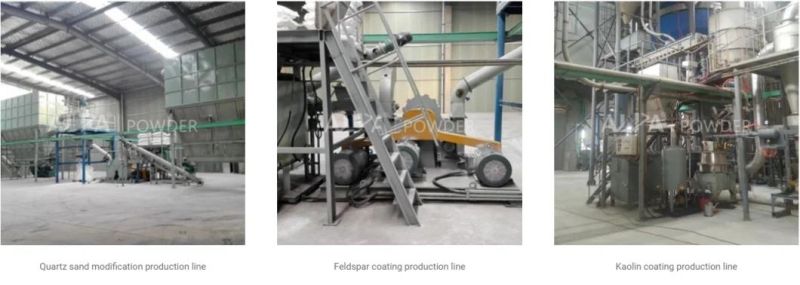

Related Engineering Case

Shandong ALPA Powder Technology Co., Ltd.(abbreviation: ALPA / Equity Code: 171033) THE WORLD'S LEADING SUPPLIER OFULTRA-FINE POWDER SOLUTIONSALPA was founded in 1999.Focus on ultra-fine ultra-pure crushing and classifying research, powder shape control, powder surface modification, and system integration of powder engineering equipment.

Shandong ALPA Powder Technology Co., Ltd.(abbreviation: ALPA / Equity Code: 171033) THE WORLD'S LEADING SUPPLIER OFULTRA-FINE POWDER SOLUTIONSALPA was founded in 1999.Focus on ultra-fine ultra-pure crushing and classifying research, powder shape control, powder surface modification, and system integration of powder engineering equipment.In the fields of ultrafine grinding and classification in the pharmaceutical, food, chemical, mineral, new materials, solid waste treatment and other industries, ALPA has mature and fully customized solutions and helps you design the ideal system to meet your needs.

WHO CHOOSE US

WHO CHOOSE USBy 2018, 37 world top 500 companies, 89 Chinese top 500 companies, 169 national key laboratories and engineering technology research centers have selected ALPA.More than 3,000 customers have chosen us

Q: What service do you supply?A: 1). We offer consultancy for project feasibility assessment, process flow definition, preliminary layout and factory building plan, project budget, project time schedule, etc.

2). We supply sample processing tests in our test station where are equipped with our various machine products, to help clients compare performances of different types of machines or process.

3). We supply project engineering, automation engineering and civil engineering.

4). We send engineers to the clients' project site and offer on-site technical instruction and supervision during the machine installation, commissioning and test run.

Q:How can I trust on your quality?

A: 1). All of the machine be tested successfully in Weifang workshop before shipment.

2). We supply one year warranty for all equipment and lifelong after-sales service.

3). We can test your material in our equipment before place the order, to ensure our equipment is suitable for your project.

4). Our engineers will go to your factory to install and debug the equipment, they will not be back until these equipment can produce qualified products.

Q:Does your company provide Engineers Abroad Service?

A: Sure, we provide it. And we can provide free training for on-site workers.

Q:How to train our staff about operation and maintenance?

A: We will provide detailed technical instructive pictures to teach them for the operation and maintenance. In addition, our engineers for guide assembly will teach your staff on site.