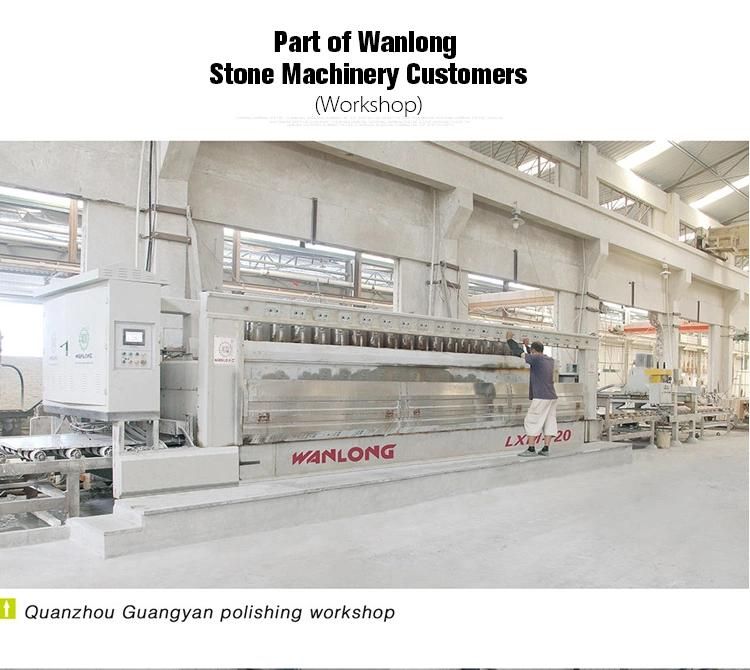

Lxm Series Wanlong Granite Marble Slabs Polishing Machine

Fujian Wanlong Diamond Tool Co., Ltd.- Type:Stone Polishing Machine

- Control:Artificial

- Automation:Automatic

- Precision:High Precision

- Application:Ceramics, Glass, Jadestone, Cement Brick, Concrete Curb, Granite, Marble, Stone

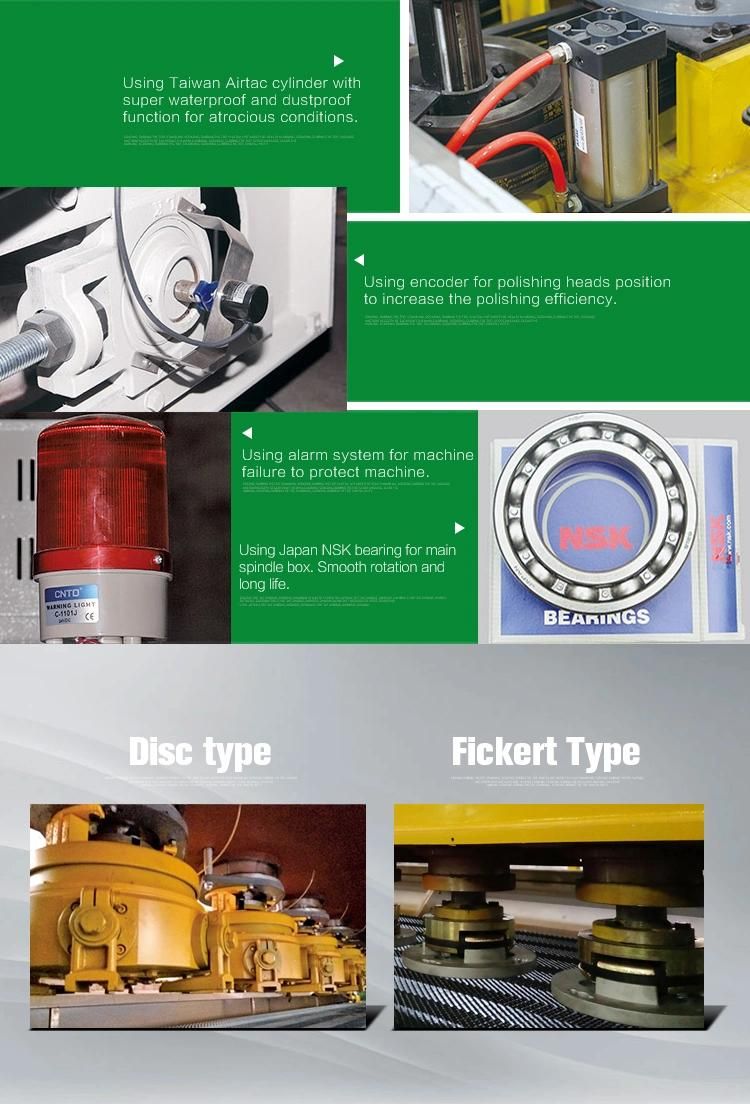

- Type for Grinding Machine:Disc Grinding Machine

Base Info

- Model NO.:LXM-12,14,16,18,20

- Grinding Machine Type:Vibration Polishing Machine

- Grinding Method:Wet Grind

- Certification:API, CCC, UL, SONCAP, GOST, ISO, CE

- Condition:New

- Model:Lxm-12,14,16,18,20

- Max.Polishing Width:1200-1400mm

- PLC:Panasonic

- Main Motor:Simense

- Polishing Heads No:12,14,16,18,20 Heads

- Automatic:Full Automatic

- Useful Working Thickness(mm:15-50mm

- Origianl:China

- Voltage:Upon Request

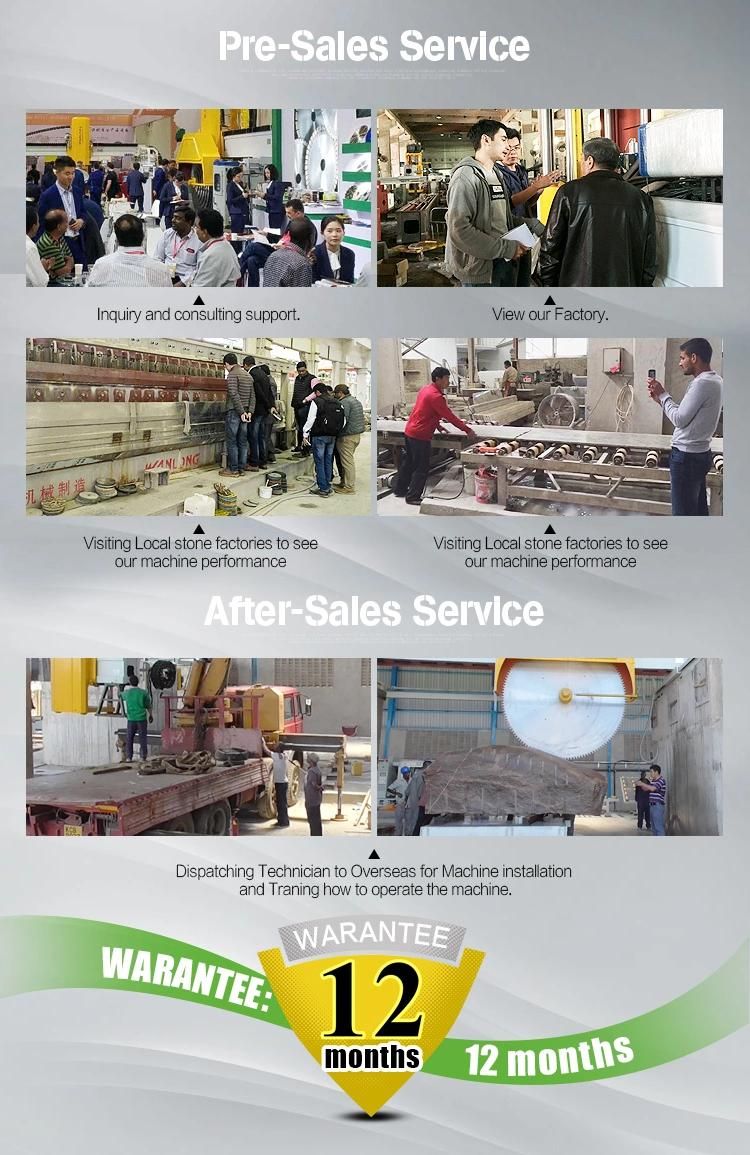

- Warranty:12 Month

- Transport Package:Saeworthy Package

- Specification:5320,5960,6600,7900*2200*2200MM

- Trademark:WANLONG

- Origin:China

- Production Capacity:10 Sets Per Month

Description

Basic Info.

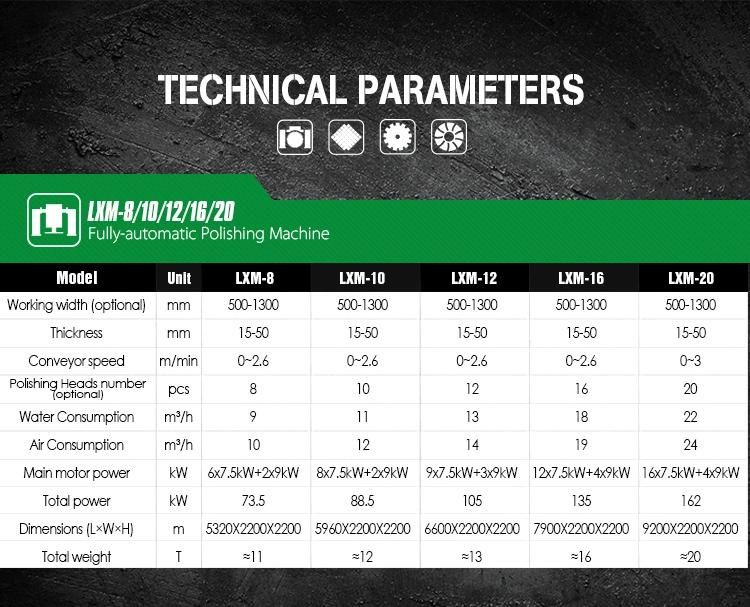

Model NO. LXM-12/14/16/18/20 Grinding Machine Type Vibration Polishing Machine Grinding Method Wet Grind Certification API, CCC, UL, SONCAP, GOST, ISO, CE Condition New Model Lxm-12/14/16/18/20 Max.Polishing Width 1200-1400mm PLC Panasonic Main Motor Simense Polishing Heads No 12/14/16/18/20 Heads Automatic Full Automatic Useful Working Thickness(mm 15-50mm Origianl China Voltage Upon Request Warranty 12 Month Transport Package Saeworthy Package Specification 5320/5960/6600/7900*2200*2200MM Trademark WANLONG Origin China Production Capacity 10 Sets Per MonthProduct Description

Full automatic polishing line:

1:Applicable for polishing the surface of granite slabs and tiles.

2:Automatic polishing machine of newly design, which absorbs the most advanced technology of granite polishing and has created several patent technologies.

3:Superior material, reasonable structure, completed processing technique, stable performance, high efficiency and energy saving.

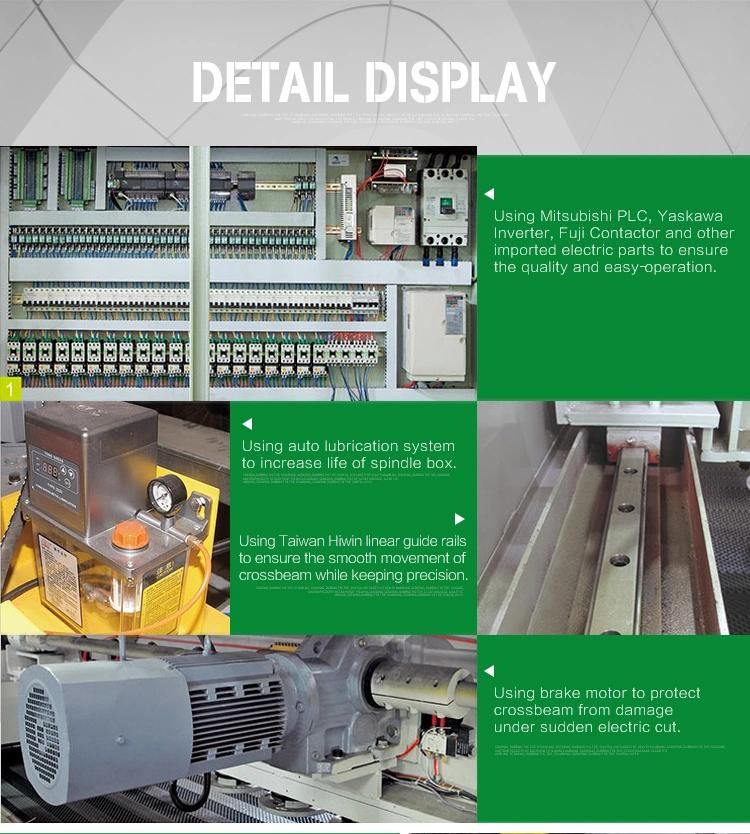

4:Electric parts are of worldwide brand, PLC control system and friendly human -machine interface via LCD to achieve computerized control.

5:Automatically detect the slab profile by laser scanning device.

6:Sensitive collision avoidance of polishing head.

| LXM-6 | LXM-8 | LXM-12 | LXM-14 | LXM-15 | LXM-16 | ||

|---|---|---|---|---|---|---|---|

| Polishing Heads number (optional) | pc | 6 | 8 | 12 | 14 | 15 | 16 |

| Working width (optional) | mm | 500-1250 | 500-1250 | 500-1250 | 500-1250 | 500-1250 | 500-1250 |

| Thickness | mm | 15-50 | 15-50 | 15-50 | 15-50 | 15-50 | 15-50 |

| Air Consumption | m³/h | 14 | 19 | 24 | 29 | ||

| Main motor power | KW | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| Dimensions (L x W x H) | mm | 6000*2100*2100 | 6700*2100*2100 | 7100*2100*2100 | 7800*2100*2100 | 8150*2100*2100 | 8600*2100*2100 |

| Main motor power | KW | 87.5 | 95 | 102.5 | 110 | 117.5 | 125 |

| Total weipht | m³/h | 10 | 14 | 18 | 22 | 26 | 30 |