China Professional Stone Crusher Manufacture

Shanghai Zenith Mineral Co., Ltd.- Type:Cone Crusher

- Application:Construction, Mineral Industry, Stone Industry

- Drive:Electric

- Crushing Style:Grinding & Impact

- Compressive Strength (For Crushing):>300MPA

- Crushing Degree:Intermediate Crusher

Base Info

- Model NO.:PY series

- Finished Surface:Hole Process

- Certification:CE, ISO, GOST

- Condition:New

- Color:Iron Grey

- Spare Parts Supply:for Whole Year

- After-Sale Service:for Whole Using Life

- Test&Installation:Engineer Assigned

- Export Markets:Global

- Transport Package:Standard Container

- Specification:CE, ISO

- Trademark:Zenith

- Origin:Shanghai Zenith, China

- HS Code:8474209000

- Production Capacity:40-850tph

Description

Basic Info.

Model NO. PY series Finished Surface Hole Process Certification CE, ISO, GOST Condition New Color Iron Grey Spare Parts Supply for Whole Year After-Sale Service for Whole Using Life Test&Installation Engineer Assigned Export Markets Global Transport Package Standard Container Specification CE, ISO Trademark Zenith Origin Shanghai Zenith, China HS Code 8474209000 Production Capacity 40-850tphProduct Description

China Professional stone crusher manufacturestone crusher manufacture has been developed to crush high or medium hardness material, such as iron ore, copper ore, limestone, quartz, granite, and sand stones, ect. And The crusher is used in metallurgical, construction, road building, chemical, silicate Industries. The cone crusher has the advantage of reliable construction, high prod activity, easy adjustment and less cost in operation. The spring release system of crusher acts an overload protection system that allows tramp to pass through the crushing chamber without damage to the crusher, use dry oil, water, two kinds of sealed formation. stone crusher manufacture made plaster stone and engine oil separated, assured reliable performance. The type of crushing chamber depend upon the size of feed and fineness of the crushed product. The standard type is applied to medium crushing, the medium type is applied to medium or fine crushing and the short head is applied to fine crushing.

stone crusher manufacture Features:

1 The stone crusher manufacture is of high reduction ratio, high performance, low power consumption, and uniform size products. The stone crusher manufacture has been used in the secondary and tertiary crushing.

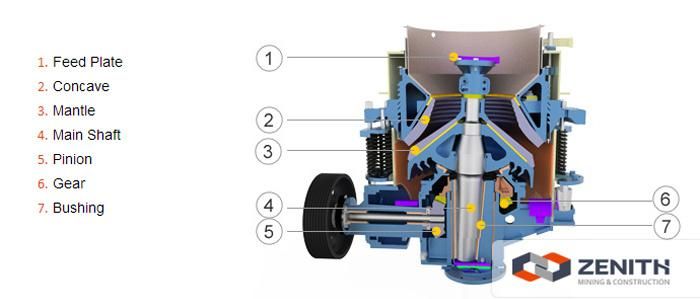

2. The cone crusher consists of body frame, transmission shaft, eccentric sleeve, cone bearing, breaking cone, supporting sleeve, adjusting sleeve, feeding part, spring, elastic coupling, lubrication part, electric part, ect.

Working Principle of stone crusher manufacture:

During operation, the motor drives the eccentric shaft shell to turn around through ahorizontal axle and a pair of bevel gear. The axle of crushing cone swings with the force of eccentric shaft shell so that the surface of the crushing wall is close to the roll mortar wall from time to time. In this way, the ores and rocks will be pressed and crooked and crushed.

1) This spring cone crusher machine is widely used in metals and non-metallic minerals, cement, construction, metallurgy, transport, sand and gravel production and especially for iron ore, gold ore, non-ferrous metal ore, granite, basalt, pebble, quartzite, sandstone, limestone and other hardness and medium hardness ore and rock.

2) The spring cone crusher machine is applied in gravel construction and artificial sand processing especially in crushing hard materials such as basalt. It is not only of high efficiency and low production costs but also of excellent shape and high-quality sand and gravel aggregate.

stone crusher manufacture technical data:

| Model | Diameter of Bottom End of Conical Crushing Head(mm) | max feeding size | adjustment range of discharge opening | capacity(t/h) | power | Rev. of Eccentric shaft | Overall dimension(mm) |

| PYB600 | 600 | 75 | 12-25 | 40 | 30 | 356 | 2234×1370×1675 |

| PYZ600 | 600 | 35 | 3-13 | 5-23 | 30 | 356 | 2234×137×1675 |

| PYB900 | 900 | 115 | 15-50 | 50-90 | 55 | 333 | 2692×164×2350 |

| PYZ900 | 900 | 60 | 5-20 | 20-65 | 55 | 333 | 2692×164×2350 |

| PYD900 | 900 | 50 | 3-13 | 15-50 | 55 | 333 | 2692×164×2350 |

| PYB1200 | 1200 | 145 | 20-50 | 110-168 | 110 | 300 | 2790×1878×2844 |

| PYZ1200 | 1200 | 100 | 8-25 | 42-135 | 110 | 300 | 2790×1878×2844 |

| PYD1200 | 1200 | 50 | 3-15 | 18-105 | 110 | 300 | 2790×1878×2844 |

| PYB1750 | 1750 | 215 | 25-50 | 280-480 | 160 | 245 | 3910×2894×3809 |

| PYZ1750 | 1750 | 185 | 10-30 | 115-320 | 160 | 245 | 3910×2894×3809 |

| PYD1750 | 1750 | 85 | 5-13 | 75-230 | 160 | 245 | 3910×2894×3809 |

| PYB2200 | 2200 | 300 | 30-60 | 490-750 | 260-280 | 220 | 4622×3302×4470 |

| PYZ2200 | 2200 | 230 | 10-30 | 200-580 | 260-280 | 220 | 4622×3302×4470 |

| PYD2200 | 2200 | 100 | 5-15 | 120-340 | 260-280 | 220 | 4622×3302×4470 |