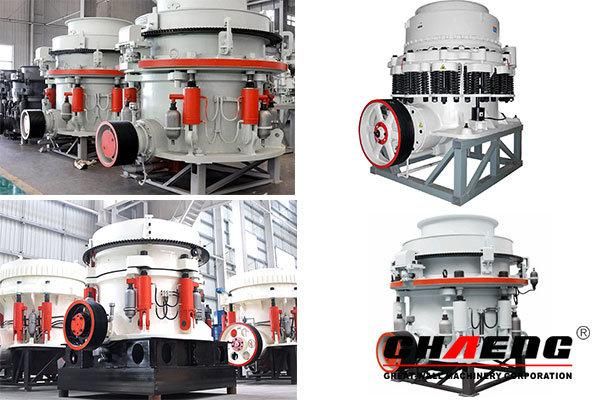

Mineral Equipment Stone Cone Crusher for Crushing Granite

Xinxiang Great Wall Machinery Co., Ltd.- Type:Cone Crusher

- Application:Construction, Mineral Industry, Stone Industry

- Drive:Hydraulic

- Crushing Style:Grinding & Impact

- Compressive Strength (For Crushing):>300MPA

- Crushing Degree:Intermediate Crusher

Base Info

- Model NO.:cone crusher

- Finished Surface:Thread Process

- Certification:CE, ISO

- Condition:New

- Color:Customized

- Feeding Size:0-350mm

- Applications Industry:Gravel Quarry, Mining, Coal Mining, Concrete Mixi

- Materials:Granite, Diabase, Basalt, Pebble, Limestone, Dolom

- Motor Power:75kw

- Transport Package:Transport Package

- Specification:45-1200TPH

- Trademark:CHAENG

- Origin:Henan

- Production Capacity:45-1200tph

Description

Basic Info.

Model NO. cone crusher Finished Surface Thread Process Certification CE, ISO Condition New Color Customized Feeding Size 0-350mm Applications Industry Gravel Quarry, Mining, Coal Mining, Concrete Mixi Materials Granite, Diabase, Basalt, Pebble, Limestone, Dolom Motor Power 75kw Transport Package Transport Package Specification 45-1200TPH Trademark CHAENG Origin Henan Production Capacity 45-1200tphProduct Description

Product DescriptionCone crusher is a modern high-performance crusher with high pendulum frequency, optimized cavity and a reasonable stroke, which is based on the introduction and absorption from foreign technology, according to the needs of the customer, and based on the principle of pyramid and the conceptual of more breaking less grinding. It is widely used in metal and non-metallic minerals, cement plant, construction, gravel and metallurgical industries.

Our hydraulic cone crusher has muti-cylinder, is the advance design of cone crusher which imports the most advanced technology, and is produced after our many years of practice. Its performance reached the advanced level of industry and is the ideal choice for the mining equipment.By using hydraulic motor to adjust the discharging opening size on-load is very easy, which makes the crushing loop balance and realizes high production efficiency. If you want to realize full-automatic control with DCS collecting and distributing control system, it only needs to install hydraulic motor position sensor to track the discharging opening size of

the crusher. All the components can be disassembled and miantained from the top or side of the crusher, and moveable cone and fixed cone are disassembled easily without dismounting the main frame and fastening bolt. It is convenient to replace liner.

Features of Cone Crusher

1 Higher production capacity, better final product particle size.

2 Replace crushing cavity if you need medium, fine and super fine product.

3 Cubic particle product.

4 Multiple production and avoid accidents and damage caused by human incorrect operation.

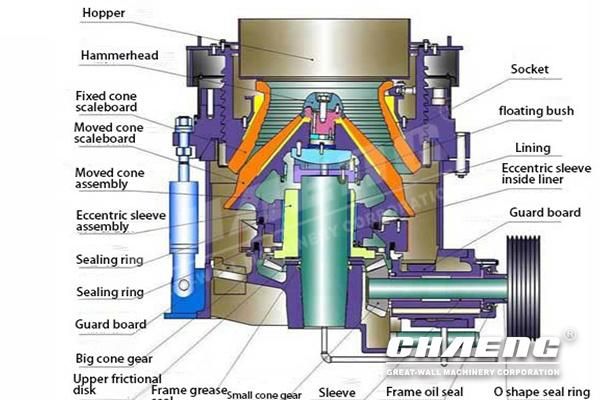

The transmission shaft is driven by the motor via the belt pulley and the triangle belt, and it drives eccentric sleeve to rotate around the main shaft. The eccentric sleeve drives the movable cone to do rotary swing movement and to make the movable cone and fixed cone sometimes be close to and sometimes go far away from the concave. The material is continually squeezed and crushed in the crushing cavity formed by the concave and the mantle. After several-time crushing, the granule is more uniform and in a cubic shape. Qualified products falls down, and the rest is crushed again.

Specification of jaw crusher

| Model | Discharge size | Installed Power | Min. capacity | Max. capacity | Chamber | Auxiliary classification |

|---|---|---|---|---|---|---|

| GCPF500 | 32mm | 400Kw | 400t/h | 530t/h | C2 thick | HP Hydraulic |

| GCPF300 | 16mm | 220Kw | 170t/h | 215t/h | M middle | HP Hydraulic |

| GCPF500 | 38mm | 400kw | 425t/h | 580t/h | C1 Super thick | HP Hydraulic |

| GCPF300 | 22mm | 220Kw | 220t/h | 260t/h | C2 thick | HP Hydraulic |

| GCPF440 | 25-51mm | 220Kw | 195t/h | 486t/h | S1 middle thick | Single Cylinder Hydraulic |

| GCPF440 | 29-51mm | 220Kw | 225t/h | 511t/h | S1 middle thick | Single Cylinder Hydraulic |

| GCPF440 | 35-54mm | 220Kw | 267t/h | 601t/h | S1 Super thick | Single Cylinder Hydraulic |

| GCPF660 | 38mm | 315Kw | 318t/h | 895t/h | S2 middle thick | Single Cylinder Hydraulic |

| GCPF660 | 41mm | 315Kw | 345t/h | 1050t/h | S1 middle thick | Single Cylinder Hydraulic |

Our service

Pre-sales Service:

The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers' request and budget, our experts make efficient, reliable solutions. Following customers' order we produce strictly, what's more, before placing the order every customer has the chance to visit XinXiang Great Wall (Chaeng) working machines or complete plant in the site.

To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, etc.

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers' plants. Necessary training about machine daily maintenance to local workers is provided also.

After-Sales department is made of well-trained employees and installation engineers, the installation engineers are special and professional members of XinXiang Great Wall (Chaeng), they are now strategically located home and abroad, working for our customers.