Mining Processing Rock Crusher Impact Crusher for Stone Crushing

Xinxiang Great Wall Machinery Co., Ltd.- Type:Impact Crusher

- Application:Construction, Mineral Industry, Stone Industry

- Drive:Hydraulic

- Crushing Style:Grinding & Impact

- Compressive Strength (For Crushing):>300MPA

- Crushing Degree:Intermediate Crusher

Base Info

- Model NO.:impact crusher

- Finished Surface:Thread Process

- Certification:CE, ISO

- Condition:New

- Color:Customized

- Feeding Size:0-1500mm

- Applications Industry:Ore Crushing, Railways, Highways, Energy, Cement,

- Motor Power:75kw

- Transport Package:Transport Package

- Specification:70-1400 t,h

- Trademark:CHAENG

- Origin:Henan

- Production Capacity:70-1400 T,H

Description

Basic Info.

Model NO. impact crusher Finished Surface Thread Process Certification CE, ISO Condition New Color Customized Feeding Size 0-1500mm Applications Industry Ore Crushing, Railways, Highways, Energy, Cement, Motor Power 75kw Transport Package Transport Package Specification 70-1400 t/h Trademark CHAENG Origin Henan Production Capacity 70-1400 T/HProduct Description

Introduction of impact crusherImpact Crusher is one kind of equipment to crushing the brittle material which compression strength no more than 350 Map, the advantage including high crushing ratio, uniform product grain and low over crushing, low energy consumption, high adjustment range of product grain size and optional crushing etc, which is mainly used in mine, metallurgy, cement, construction material, coal etc for secondary crushing and fine crushing the medium hardness material.

Impact crusher is widely used in water and electricity, highway, artificial aggregate, crushing and other industries. This series of impact crusher has unique structure.It's equipped with high chrome hammer.Its unique counterattack lining is suitable for hard rock crushing and energy efficient. Nesting particle size can be adjusted to simplified crushing process. This crusher has large crushing ratio, high crushing efficiency, cubic shape and optional broken, etc.

Advantages of impact crusher

1. Multi-cavity uniform crushing, suitable for crushing rock with medium and below hardness, high efficiency and energy saving.

2. The chunky and large material inlet makes it easy to arrange the production line and increase inlet size.

3. Full hydraulic pressure start-up, and it is easy for maintenance and changing spare parts.

4. New type wear-resistant material assures the hammer, impact bracket and liner have long service life.

5. It has the functions of 3-stage crushing and shaping. The final products are in cubic shape without tension crack. The discharging size is adjustable, which simplifies the crushing process.

Working process of impact crusher

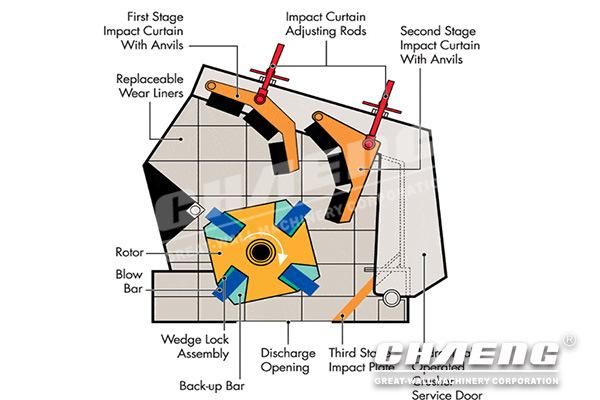

The impact crusher is a crushing machine that uses impact energy to break up materials. When the impact crusher is working, the rotor rotates at a high speed under the driving of the motor. When the material enters the action area of the flat hammers, it is broken through the collision with the hammers on the rotor, and then is thrown to the impact device for breaking again, and then rebounds from the impact plat to the hammer action zone. The process is repeated, the material enters the first, second and third impact chambers in order from large size to small size until the material is crushed to the required particle size and discharged from the outlet port.

Specification of impact crusher

Specification of impact crusher | Model | Rotator Specification (mm) | Inlet Size (mm) | Max. Feed Size (mm) | Output (t/h) | Power (Kw) | Overall Dimension (mm) | Weight (t) |

|---|---|---|---|---|---|---|---|

| PF-1210 | 1250×1050 | 400×1050 | 350 | 70-120 | 110-132 | 2690×2338×2890 | 14.9 |

| PF-1214 | 1250×1400 | 400×1430 | 350 | 130-180 | 132-160 | 2690×2338×2890 | 18.6 |

| PF-1310 | 1300×1050 | 490×1170 | 400 | 80-140 | 110-160 | 2780×2478×2855 | 16.2 |

| PF-1315 | 1320×1500 | 860×1520 | 500 | 160-250 | 180-260 | 3096×3273×2667 | 19.3 |

| PF-1415 | 1450×1500 | 1145×1520 | 950 | 220-450 | 220-315 | 3745×3022×3519 | 27 |

| PF-1520 | 1520×2000 | 830×2050 | 700 | 300-500 | 315-440 | 3581×3560×3265 | 38.7 |

| PF-1818 | 1800×1800 | 1600×1850 | 1000 | 600-850 | 650-900 | 4180×4200×4900 | 75 |

| PF-2024 | 2000×2400 | 1800×2430 | 1200 | 800-1100 | 1120 | 4800×4740×4180 | 120 |

| PF-2326 | 2300×2600 | 2260×2640 | 1500 | 1000-1400 | 1250-1400 | 5360×5075×4680 | 148 |

Our service

Pre-sales Service:

The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers' request and budget, our experts make efficient, reliable solutions. Following customers' order we produce strictly, what's more, before placing the order every customer has the chance to visit XinXiang Great Wall (Chaeng) working machines or complete plant in the site.

To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, etc.

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers' plants. Necessary training about machine daily maintenance to local workers is provided also.

After-Sales department is made of well-trained employees and installation engineers, the installation engineers are special and professional members of XinXiang Great Wall (Chaeng), they are now strategically located home and abroad, working for our customers.